Light Weight Deflectometer (LWD) from Zorn Instruments

- Used for compaction control and bearing capacity estimation

- Unbound or partially bound layers (sub-grade, sub-base, base)

- Measures the deflection and stiffness (modulus)

- Immediate repeatable results so that on-site decisions can be made straight away

- Meets ASTM E2835-21 (2021) standard and Test Method Q258A Dynamic Modulus of Deformation – Light Falling Weight Device – Accelerometer Type – (DTMR QLD) March 2021

Compaction Control

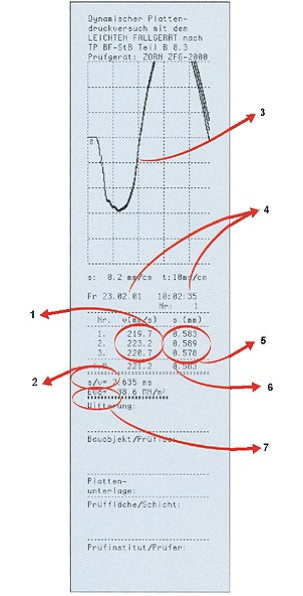

The Light Weight Deflectometer measures a deflection and calculates a modulus value based on the force required to generate a given deflection. Modulus is the most accurate and independent means for judging deformation (stiffness) and, thus, a material’s level of compaction.By measuring the modulus value, the Light Weight Deflectometer provides the link between the design specification (design modulus value) and the actual site condition (in-situ modulus value).

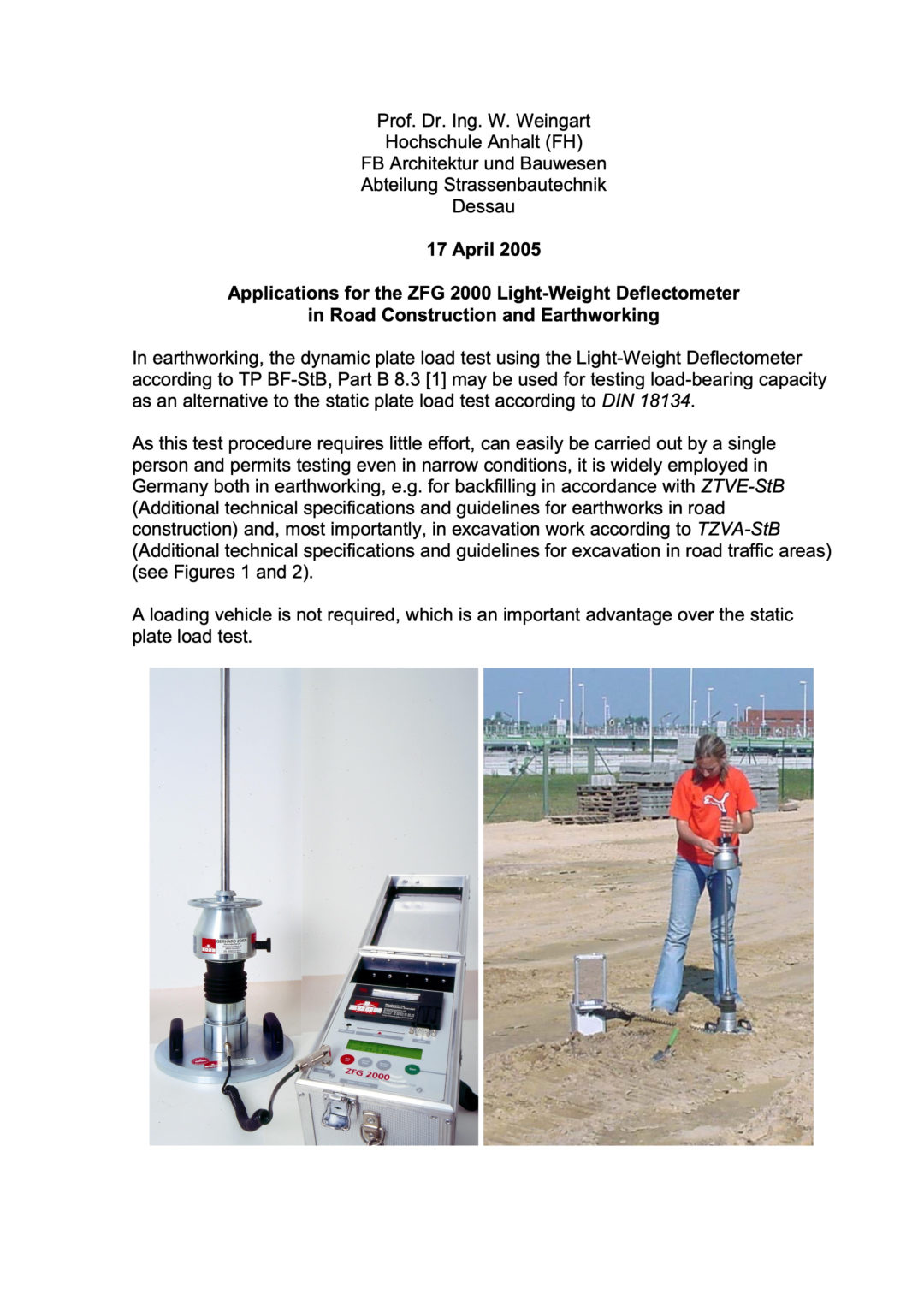

Light Weight Deflectometer’s (LWD’s) are a light weight, portable tool used to determine the stiffness of unbound materials (subgrade/subsoils and base layers, granular layers & backfilling materials) or sometimes partially bound material (e.g. stabilised) during construction or pavement rehabilitation.

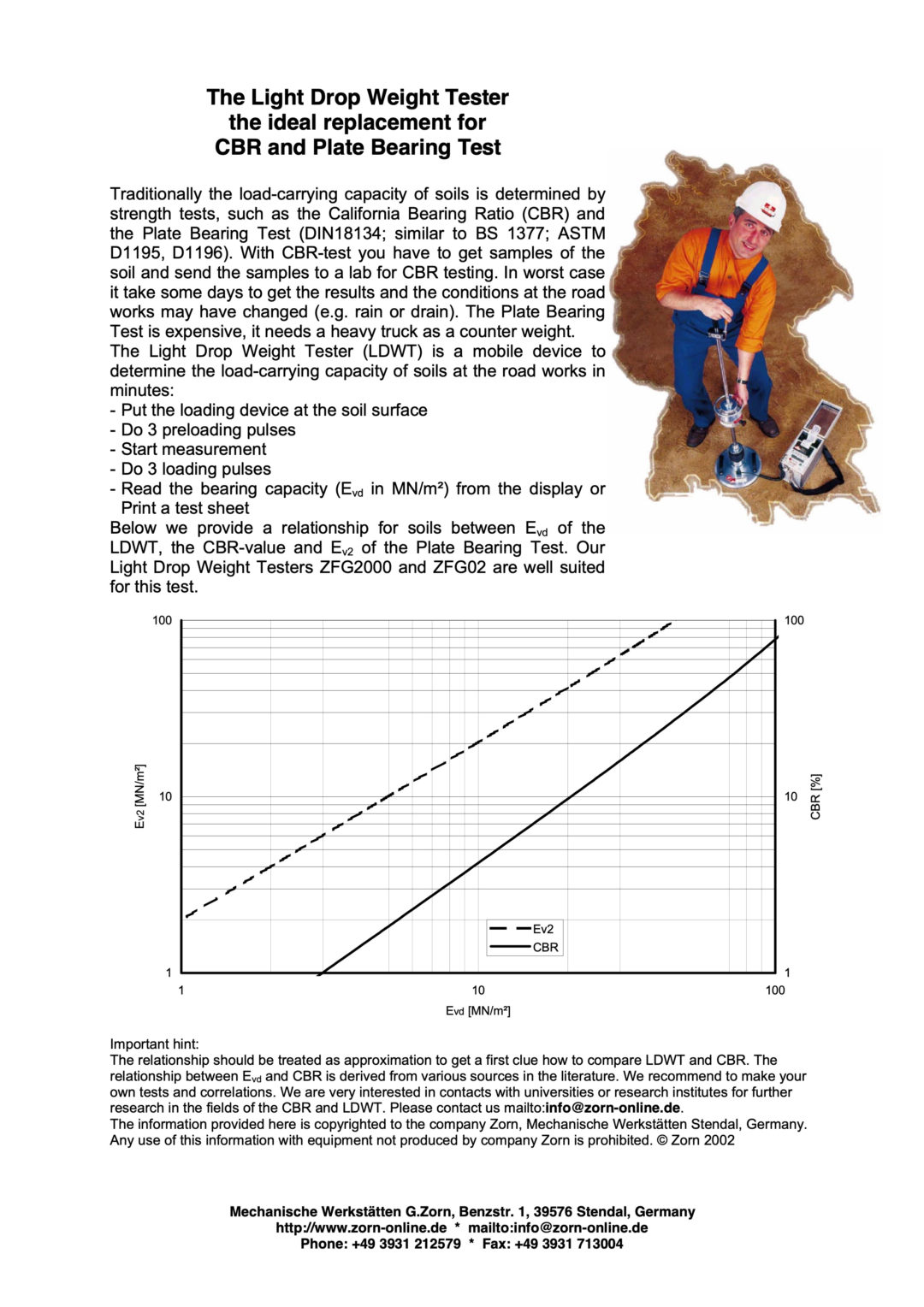

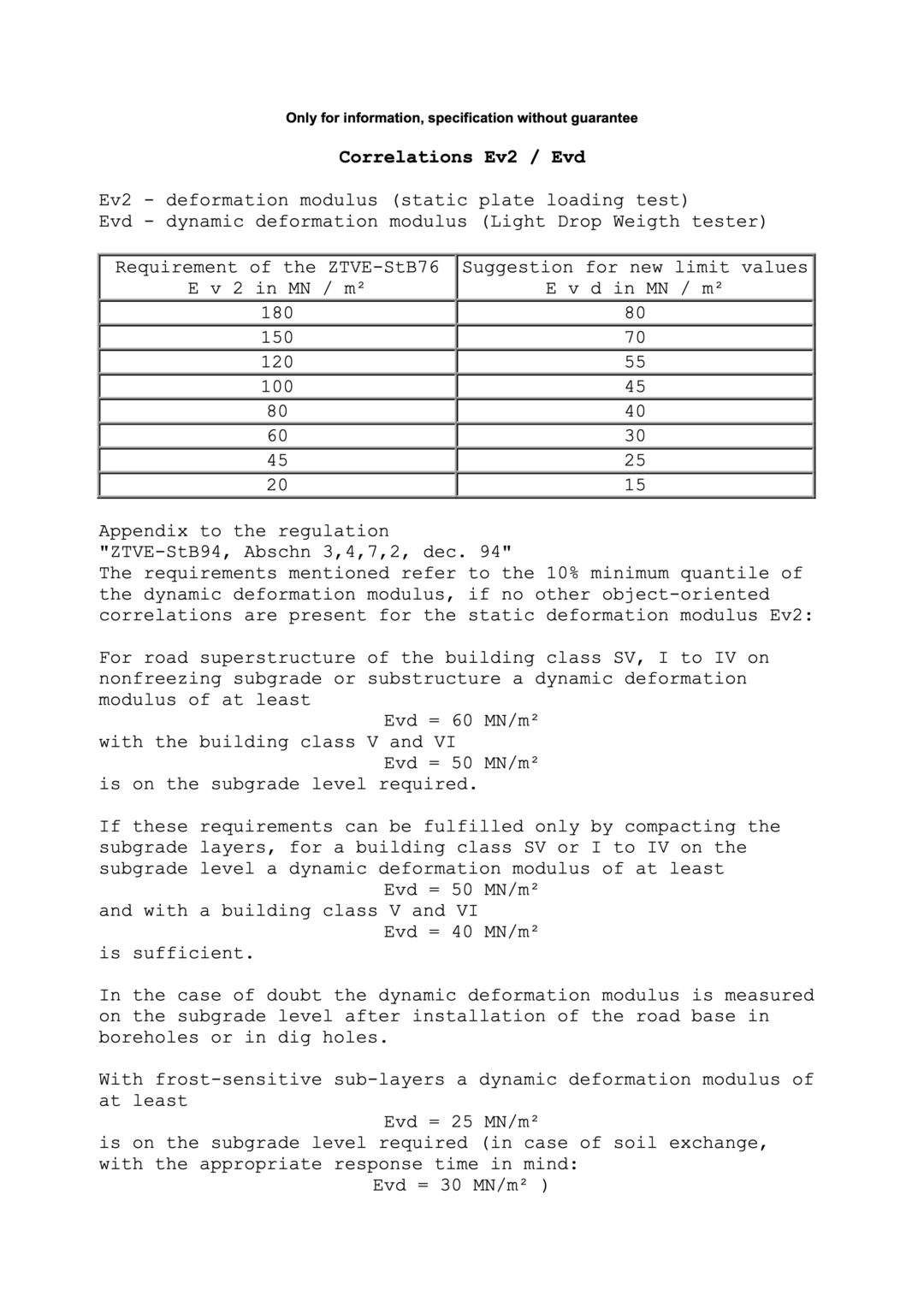

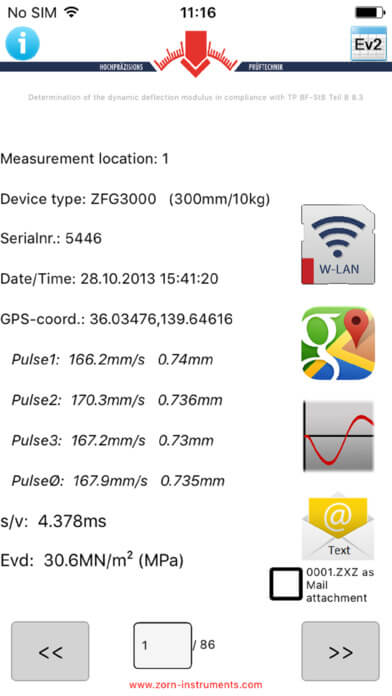

The Zorn LWD’s measures the dynamic modulus of deformation Evd in the range from 15 up to 140 MN/m².

Using extensions to the Zorn LWD’s, dynamic CBR (California Bearing Ratio) can also be measured in-situ in the field and also laboratory CBR in a cylinder can be simulated.

The Light Weight Deflectometer (LWD) ZFG 3000 and ZFG 3.1 from Zorn Instruments are compaction control methods designed to ASTM E2835-21 (2021) Standard Test Method for Measuring Deflections using a Portable Impulse Plate Load Test Device, TPBF-STB Part B8.3 (2016) from the German Road and Transport Research Association (BaST) and Department of Transport and Main Roads Queensland (DTMR) Test Method Q258A Dynamic Modulus of Deformation – Light Falling Weight Device – Accelerometer Type (March 2021).

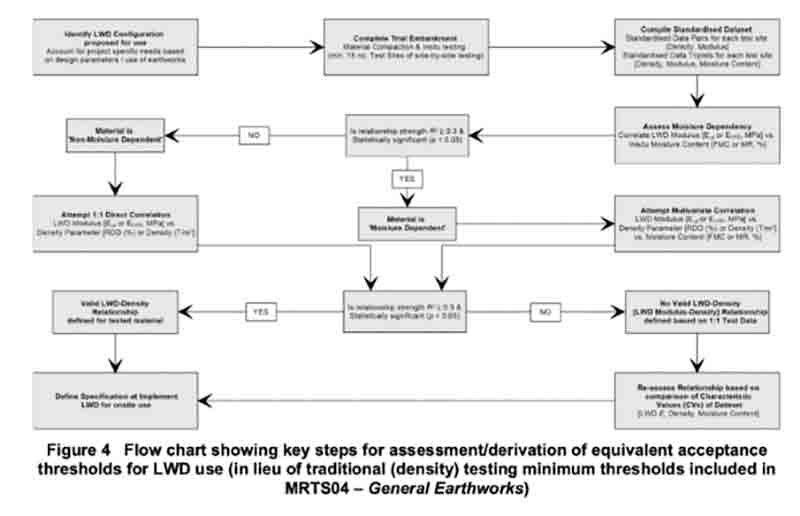

Check out the latest research on alternatives to the traditional density approach to compaction. One outcome was the development of this Draft Technical Note – Guidance on Use of Light Weight Falling Deflectometers (LWDs) to be Accepted as an Alternative Method for Verification of Earthworks Compaction Requirements – June 2021.

The Laboratory Light Weight Deflectometer (LWD) ZORN ZFG LAB is used to determination the relationship between moisture content and modulus of unbound granular material on laboratory compaction samples (Proctor compaction process). Deflection is measured using the Lab LWD on laboratory compacted samples in a Proctor mould at a range of moisture contents for a given material type. This method is used to determine target moduli or deflection values to achieve a given density and apply these values for LWD field testing. The Laboratory Light Weight Deflectometer ZORN ZFG LAB meets ASTM E3331-22 – Standard Test Method for Measuring Target Modulus Using the Light Weight Deflectometer on Laboratory Compaction Characteristic Samples.

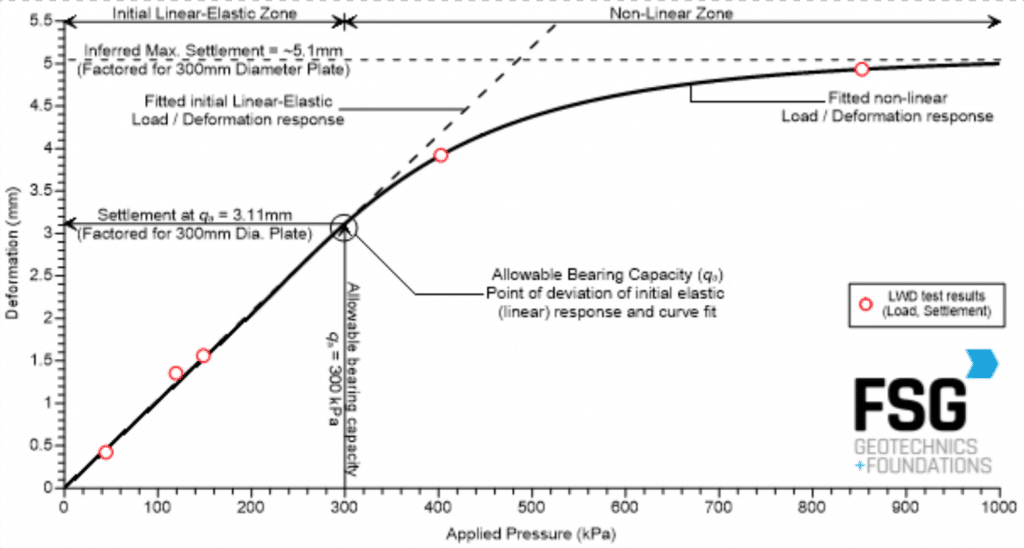

Bearing Capacity

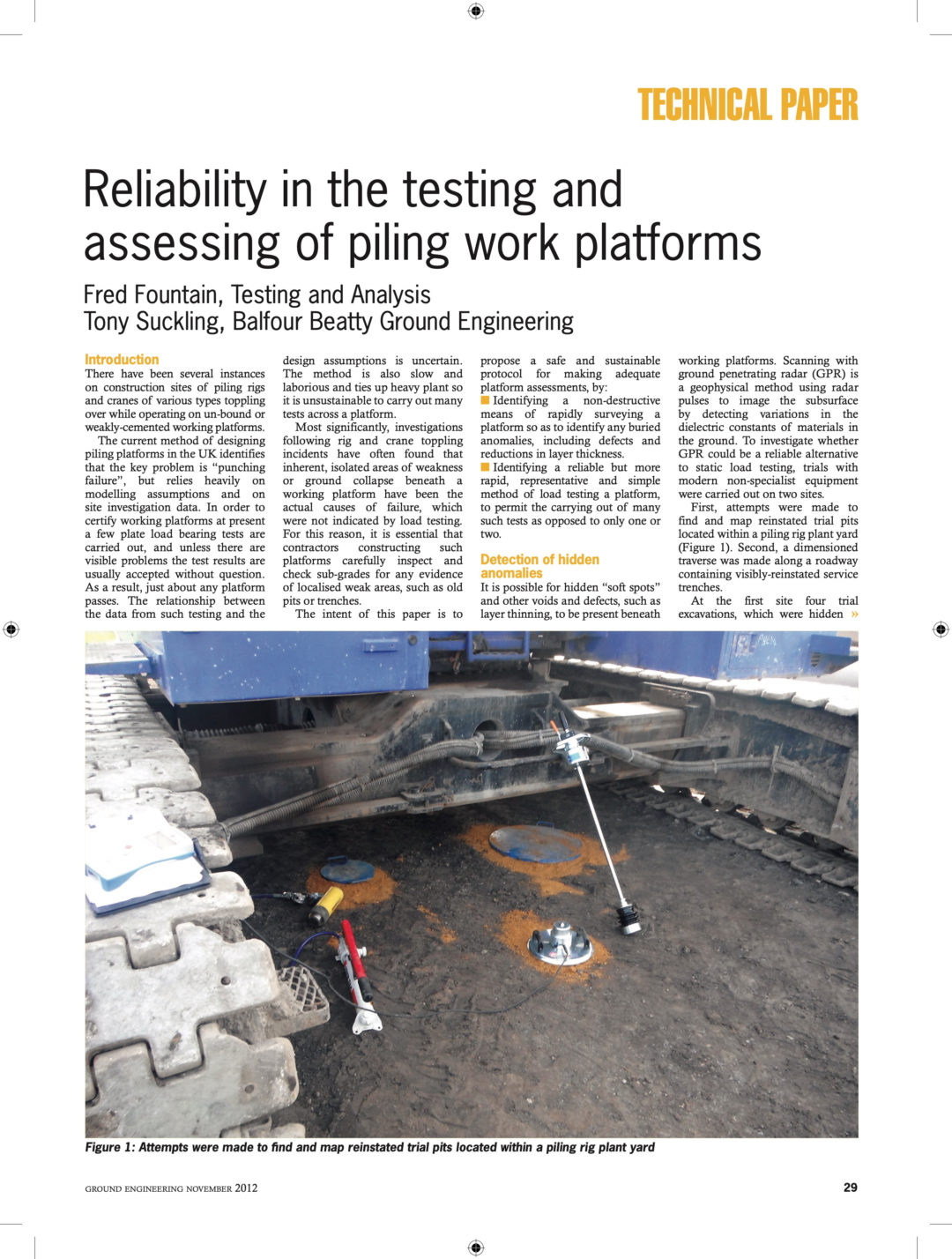

The LWD is used for allowable bearing capacity Quality Assurance (QA) of prepared surfaces, prior to the installation of permanent structures (e.g. slabs, footings, pavements) or temporary works platforms (crane pads, piling rigs). The bearing capacity under the plate is from 30 – 400 kPA, achieved by changing plate diameters, drop weights and drop height.

Let’s take a crane lift. The insitu ground conditions have been identified in order for the temporary works platform to be designed. However, immediately prior to the crane lift, the insitu conditions are required to be verified to determine if the bearing capacity of a site has altered due to changing conditions, like rain. The LWD is used for this purpose.

Applications

The LWD is well suited to in-situ testing of earthworks during construction, particularly where common techniques (e.g. nuclear gauge/sand replacement) are not appropriate or cost effective.

LWD’s are more accurate than the traditional DCP, especially in soft/loose materials or for estimating allowable bearing capacity.

Applications include flexible pavements, unsealed roads and mine access roads, tunnels, railway track beds, airport runway and taxiways, hard standing areas, dam construction, canal building, embankments, temporary works platforms (crane pads and piling rigs), building foundations (footings and slabs), wind farms, pipe laying, contaminated sites and tank farms.

Advantages

The advantages of the Zorn ZFG Light Weight Deflectometers (LWD’s) include:

Faster

- Results immediately available so on-site decisions can be made straight away with no construction delay.

- Approx 3 minutes per test

- Using the Web based Zorn FG-WebApp on your smartphone or tablet to easily and quickly import, edit and evaluate the data (directly on site) and send it as a data collection or in the form of completed high-quality test reports.

More accurate and repeatable

- Direct deflection readings: accelerometer directly connected to the base plate.

- High levels of repeatability

Non destructive

- As a surface based test, the LWD has no footprint that needs to be remediated

- The surface is not disturbed, which is very important for contaminated sites

- Granular and geo-reinforced materials can be tested

More representative

- Provides a more representative picture of a pavement’s ability to handle traffic loads than density or CBR measurements.

- By measuring the modulus value, the LWD provides the link between the pavement design specification (design modulus value) and the actual site condition (in-situ modulus value).

- Provides calibration of Intelligent Compaction (IC) rollers output in relation to the pavement design specification (modulus value) for a specific site.

- By pairing with the PANDA Instrumented DCP, you can increase the depth of the zone of assessment e.g. for deep lift compaction

Without errors

- Equipment is instrumented (data is automatically and accurately recorded)

- Results are machine produced (overcoming manual data recording, transposition or calculation errors and fictitious results)

- Seamless flow of data from measuring equipment to report production

GPS located and time stamped – know where and when every test is done

- GPS-System for immediate determination of test position integrated with Google Maps.

Visually presented results

- Results including graphical outputs immediately available so integrity of results can be checked

- Data interpretation software allows data storage, analysis and manipulation and easy inclusion into reports.

Improved safety

- Less time testing near traffic at the construction site.

- Suitable for use in confined spaces and difficult to access locations, with no support equipment required.

Cost effective

- One person operation: portable, lightweight and easy to use.

- Cost-effective for completion at locations where equipment/plant has to be stopped whilst the test is completed.

- No additional counter weight vehicle or support is required.

Clients include those involved in pavement construction, pavement rehabilitation, material testing, geotechnical testing, pavement investigation and site investigation and include road authorities, councils, asset managers, mines, mobile crane operations, engineering and construction groups, EPCM’s, subcontractors, geotechnical consultancies and research organisations.

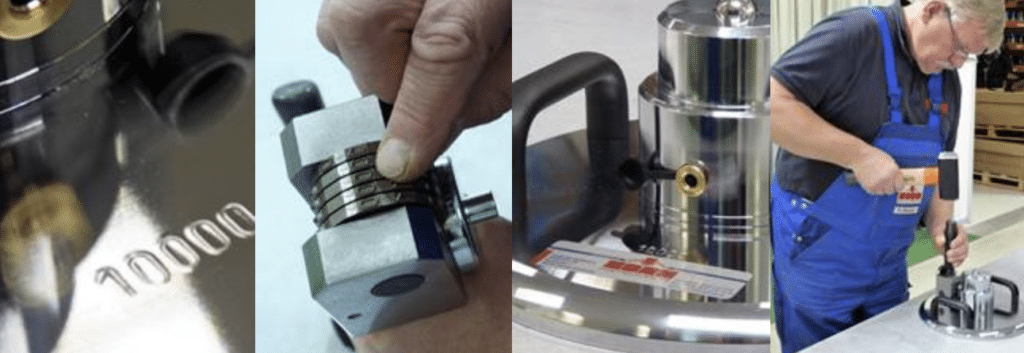

Light Weight Deflectometer (LWD) Calibration, Service and Spare Parts

Insitutek are proud to represent Zorn Instruments Light Weight Deflectometers (LWD’s) in Australia, New Zealand and the Pacific Islands and provide a very high level of client support.

We offer a complete spectrum of services including after-sale technical support, servicing, repairs, and calibrations. Our clients have exclusive access to the only Light Weight Deflectometer calibration and service centre in the Southern Hemisphere. Run by Zorn Instruments trained technicians, our service centre is also well stocked with spare parts. Our Australian based Zorn Instruments Calibration Stand and Service Centre is exclusive to Zorn clients and saves you significant down time compared to calibration and repairs overseas.

To find out more, Contact Us.

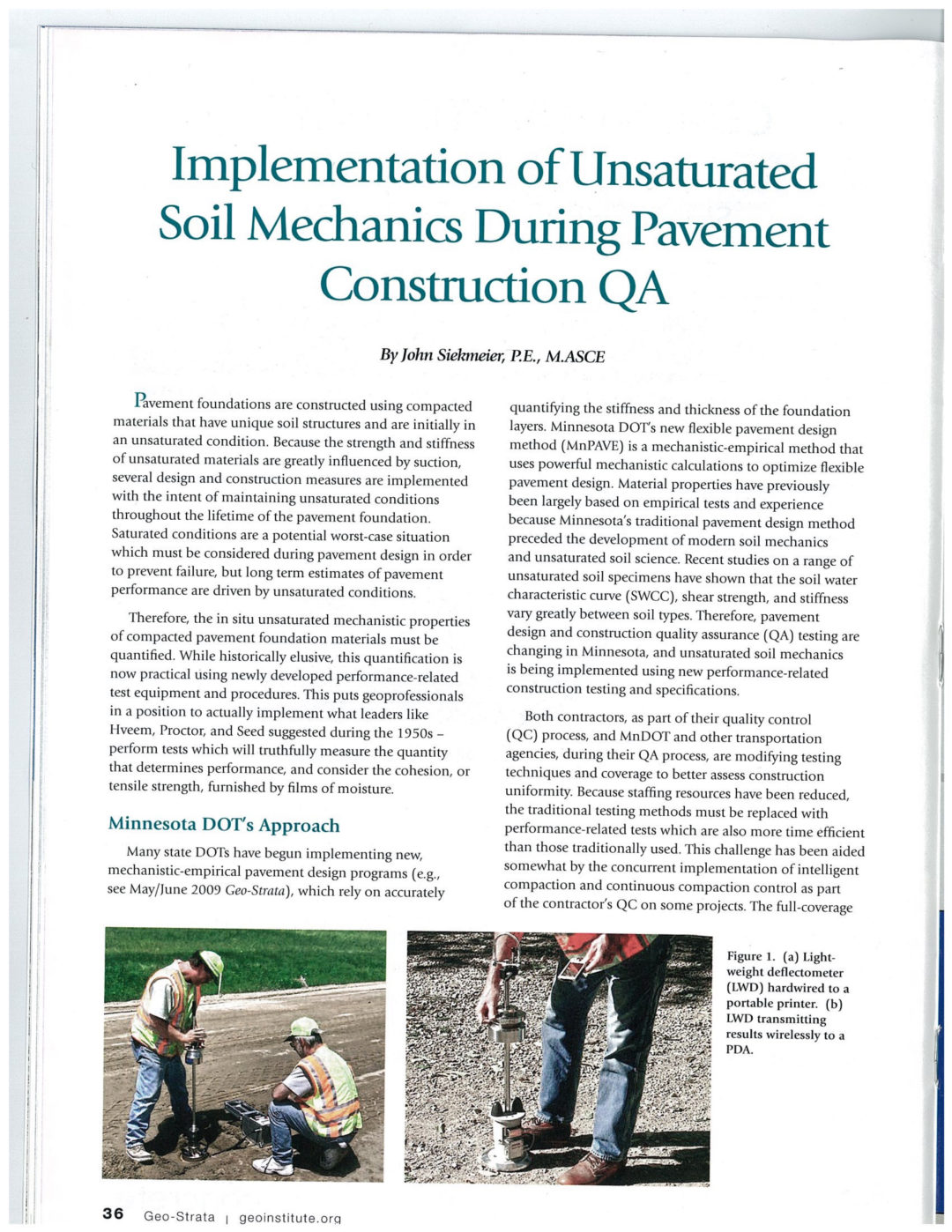

For a highway to perform well over the long term, its soil and aggregate layers need to provide a stiff, stable foundation. Inspections are required during construction to ensure that pavement foundation materials have been compacted enough to ensure this condition. Light Weight Deflectometer’s (LWD’s) are used to determine the stiffness of unbound materials (subgrade/subsoils and base layers, granular layers and backfilling materials) during construction. The device measures a deflection and estimates a modulus value (Evd) based on the force required to generate a given deflection for that soil type. Modulus is the most accurate and independent means for judging deformation (stiffness) and, thus, a material’s level of compaction.By measuring the modulus value, the Light Weight Deflectometer (LWD) provides the direct link between the design specification (modulus value) and the actual site condition (modulus value).

For a highway to perform well over the long term, its soil and aggregate layers need to provide a stiff, stable foundation. Inspections are required during construction to ensure that pavement foundation materials have been compacted enough to ensure this condition. Light Weight Deflectometer’s (LWD’s) are used to determine the stiffness of unbound materials (subgrade/subsoils and base layers, granular layers and backfilling materials) during construction. The device measures a deflection and estimates a modulus value (Evd) based on the force required to generate a given deflection for that soil type. Modulus is the most accurate and independent means for judging deformation (stiffness) and, thus, a material’s level of compaction.By measuring the modulus value, the Light Weight Deflectometer (LWD) provides the direct link between the design specification (modulus value) and the actual site condition (modulus value). Load bearing capacity. The subgrade must be able to support loads transmitted from the pavement structure. This load bearing capacity is often affected by the degree of compaction, moisture content, and soil type. A subgrade that can support a high amount of loading without excessive deformation is considered good.

Load bearing capacity. The subgrade must be able to support loads transmitted from the pavement structure. This load bearing capacity is often affected by the degree of compaction, moisture content, and soil type. A subgrade that can support a high amount of loading without excessive deformation is considered good.