Harsh Pilbara heavy haul rail conditions puts PANDOSCOPE® to the test

There is nothing like jumping in at the deep end!

With buy in from Fortescue Metals Group, BHP and Rio Tinto, we brought together our supply partner, Sol Solution from France, and the extreme conditions of deep fouled ballast and the Pilbara climate to test to see how the PANDOSCOPE® would operate. Suffice to say, the outcomes were very positive and we have subsequently started our first projects using the PANDOSCOPE® in Australia.

So what is the PANDOSCOPE®?

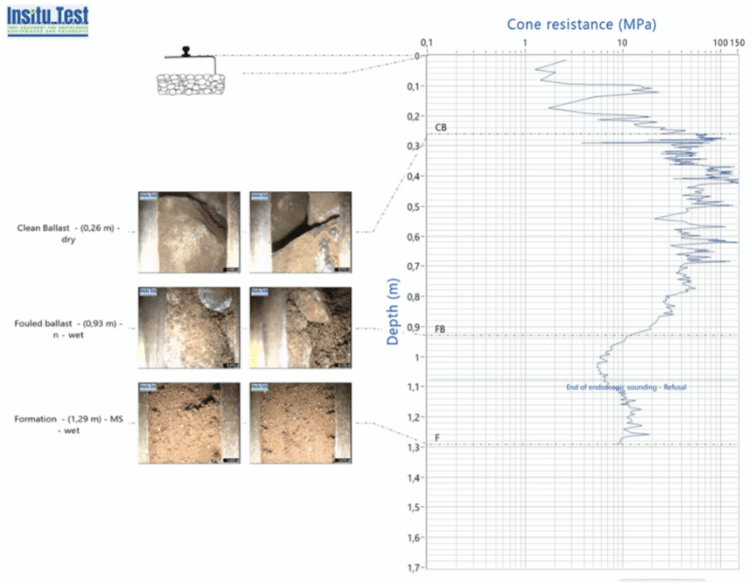

The PANDOSCOPE® is a coupling of the PANDA® Instrumented Dynamic Cone Penetrometer (DCP) (tip resistance vs depth profile) and Geoendoscopy (down the hole imagery).

How is the PANDOSCOPE® used in rail applications?

The PANDOSCOPE® is as a non-destructive rail track ballast and formation condition assessment method typically used when planning track maintenance and renewal.

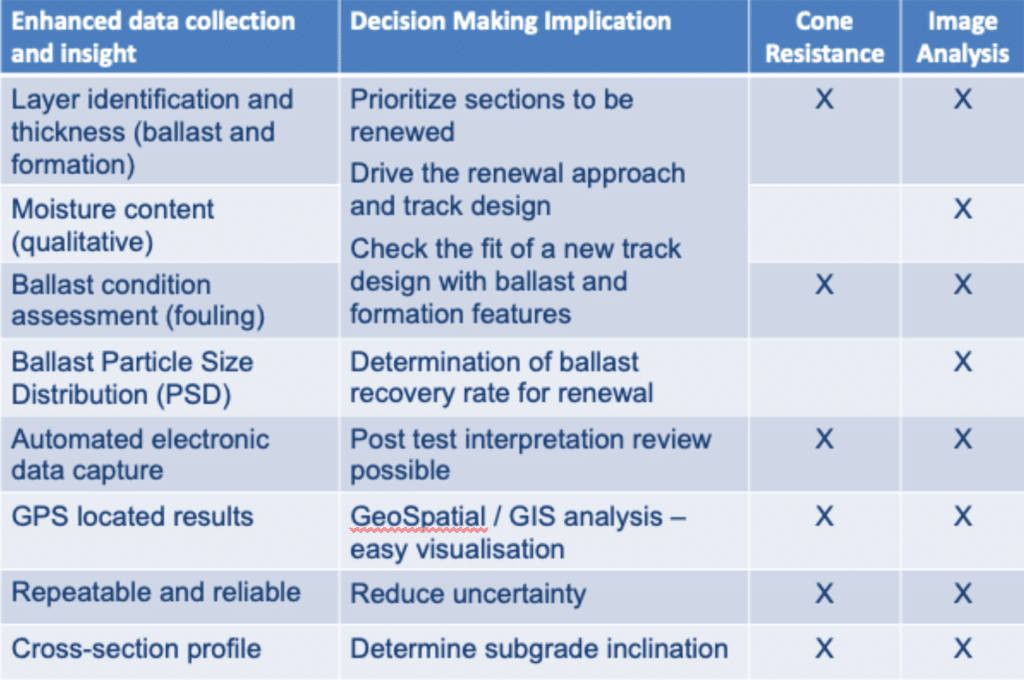

In rail applications, the PANDOSCOPE® measures geotechnical aspects of the track bed and can provide the following outcomes:

- Layer characterisation for ballast and formation (identification, thickness, water content (qualitative), estimation of the soil grain size distribution and ballast condition (ballast fouling) assessment)

- Mechanical information: cone resistance (direct measurement) or CBR or other parameters with correlations

What was the purpose of the initial trials?

To understand the ballast and formation condition, the miners were looking to evaluate the PANDOSCOPE® against the current methods of pot holing, DCP testing, visual observation and sampling, as well as Ground Penetrating Radar (GPR) data.

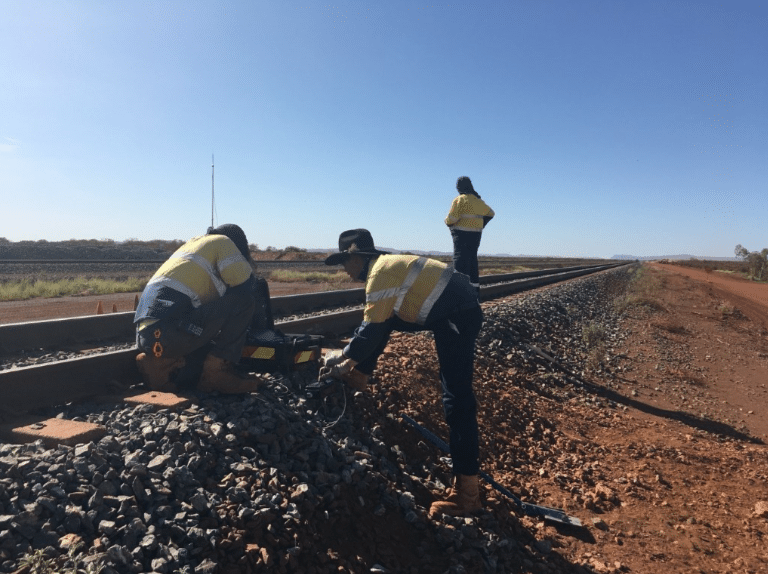

Heavy haul iron ore rail in the Pilbara are typically operational 24/7. Hence, the miners really wanted to understand if it was possible to test between trains working under lookout protection.

From our own perspective, we wanted to understand how the PANDOSCOPE® would stand up to the extreme conditions of deep fouled ballast and the Pilbara climate.

What have we learned from our PANDOSCOPE® work in the Pilbara so far?

Rio Tinto, BHP and Fortescue Metals Group all have exceptionally high levels of safety requirements so one breakthrough was approval to test between trains working under lookout protection.

One of the things we love about working with Sol Solution, our supply partner, is that innovation is baked in their corporate blood. Every year, more than 10% of their turnover is allocated to R&D. In our initial trials, for example, we discovered that the fouled ballast could be consistently stiffer over greater depths than many other heavy haul and passenger networks we had worked on in Europe, the Americas and Asia. Within a few weeks of the initial trials, the R&D team had come up with innovative solutions to the practical issues we had experienced and in subsequent projects in the Pilbara, these have proved very effective.

Other highlights for discussions with our clients include:

- No destabilisation / disturbance of the track which is important if renewal works are delayed or do not proceed

- Cost effective methodology with reduced cost per hole compared to conventional approaches like potholing and reduced head count on site. For remote site working, this also means less flights and accommodation are required.

- Better informed decision making

We look forward to bringing this impressive PANDOSCOPE® testing approach to a wider audience, helping our clients get clear insight on what’s going on below the surface so they can make well informed decisions in a timely manner.

Forensic analysis of pavements is one example. Investigation into the walls of underground structures (like tunnels) is another.

For more information on how the PANDOSCOPE® could benefit you, visit our website.

Fortescue Metals Group is a global leader in the iron ore industry, with a unique culture, innovation and industry-leading development of world class infrastructure and mining assets in the Pilbara, Western Australia.

Rio Tinto mines metals, producing materials essential to human progress. These include iron ore for steel, aluminium for cars and smartphones. Copper for wind turbines, electric cars and the pipes that bring water to our home, borates hat help crops grow and titanium for paint. Our focus was their iron ore operations.

BHP is a world-leading resources company who extract and process minerals, oil and gas primarily in Australia and the Americas. Our focus was their iron ore operations in the Pilbara.

That was really useful and informative yesterday – started a lot of discussion around here.

After scouring the market, we settled on the PANDA DCP test equipment as it offered the technical capability and, moreover, the flexibility required to work in the restricted environment our project presented; overhead clearance typically at 1500mm but as low as 1200mm. We had a unique problem that required a unique solution and that’s precisely what we found through the team at Insitutek and the PANDA equipment. The ease of assembly, intuitive operability and compact nature of the equipment, made light of the numerous soundings we required across a widely dispersed area.

We have been very happy with the support from Insitutek. They are knowledgeable and have been super responsive and flexible to our needs.

Insitutek Blogs

We find clients are often looking for ways to improve geotechnical testing outcomes and do it more efficiently at the same time. This drives their buying decision making. Australian Soil and Concrete Testing (ASCT) was a case in point when they were searching for Plate Load Test equipment for their upcoming Collector Wind Farm project. Some of the things that motivated them include: […]

We are excited to introduce the addition of a new Liquefaction Risk Estimation module in WebSprint©. Paired with our cutting-edge products, PANDA® and GRIZZLY®, this module enables you to assess the liquefaction risk of soils exposed to seismic stress. PANDA® Instrumented DCP: This cutting-edge tool provides dynamic penetrometer soundings, delivering precise data crucial for seismic risk evaluations. GRIZZLY® […]

The Australian Geomechanics Society is gearing up for a series of geotechnical events across VIC, WA, NSW, and SA-NT. We are thrilled to inform you that we will be sponsoring and attending these exciting geotechnical events, and we would love for you to join us. It’s a fantastic opportunity to catch up, explore our booth (VIC), and stay informed about […]