The Science

TERRA-3000® requires the presence of clay and silt fines to improve the mechanical and hydraulic performance of soil. Soils with a wide range of clay content can successfully be treated.

TERRA-3000® is a chemically engineered Amine based liquid concentrate that is diluted with water during treatment. It acts as a catalyst to permanently and irreversibly alter the properties of soil colloids.

TERRA-3000® produces an electro-physical reaction (ion exchange) in the cohesive fines (clays, and silts) during treatment. The ion exchange reduces the surface tension of water in soil colloids, so that the barrier film surrounding colloids is dispersed.

As a result, treated soil particles can more closely associate during compaction and the capillary action of the treated soil particles is effectively broken down.

It is not a binder or binding agent, meaning that pavement layers which are treated with TERRA-3000® are considered unbound and retain the advantage of flexibility at strength over bound pavements.

When applied as directed to suitable materials, TERRA-3000® increases the stiffness of stabilised soils and prevents the ingress of water.

Material Suitability

TERRA-3000® requires the presence of clay and silt fines to improve the mechanical and hydraulic performance of soil. It is suitable and safe to use in environmentally sensitive areas such as rivers and lakes. It doesn’t leach and leaves no reside.

TERRA-3000® requires the presence of clay and silt fines to improve the mechanical and hydraulic performance of soil. It is suitable and safe to use in environmentally sensitive areas such as rivers and lakes. It doesn’t leach and leaves no reside.

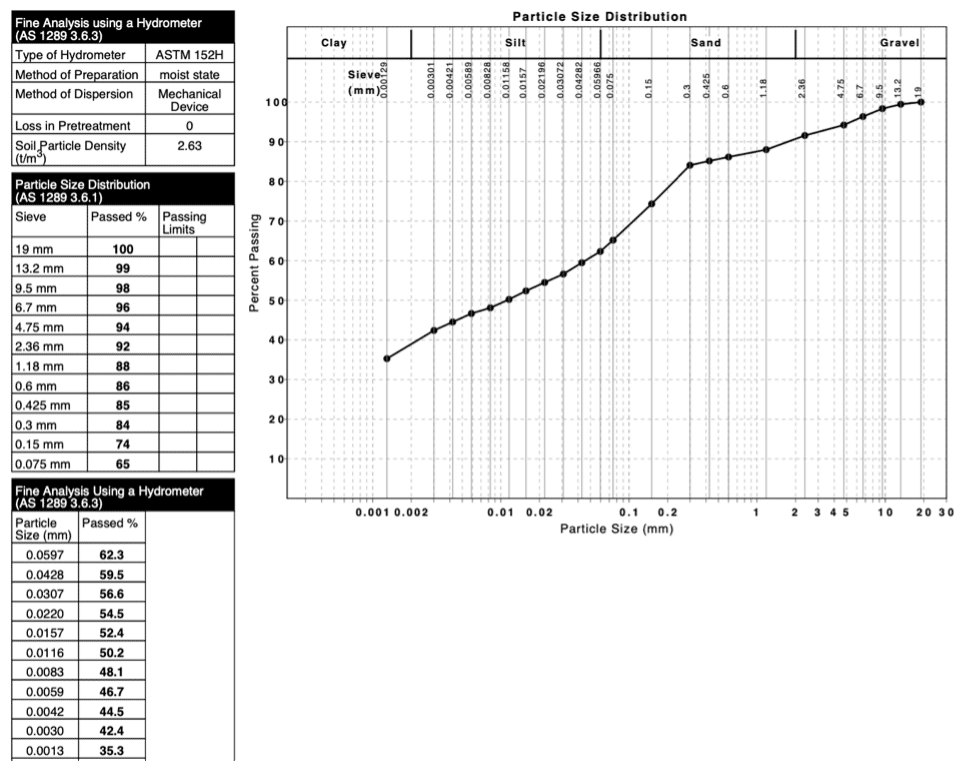

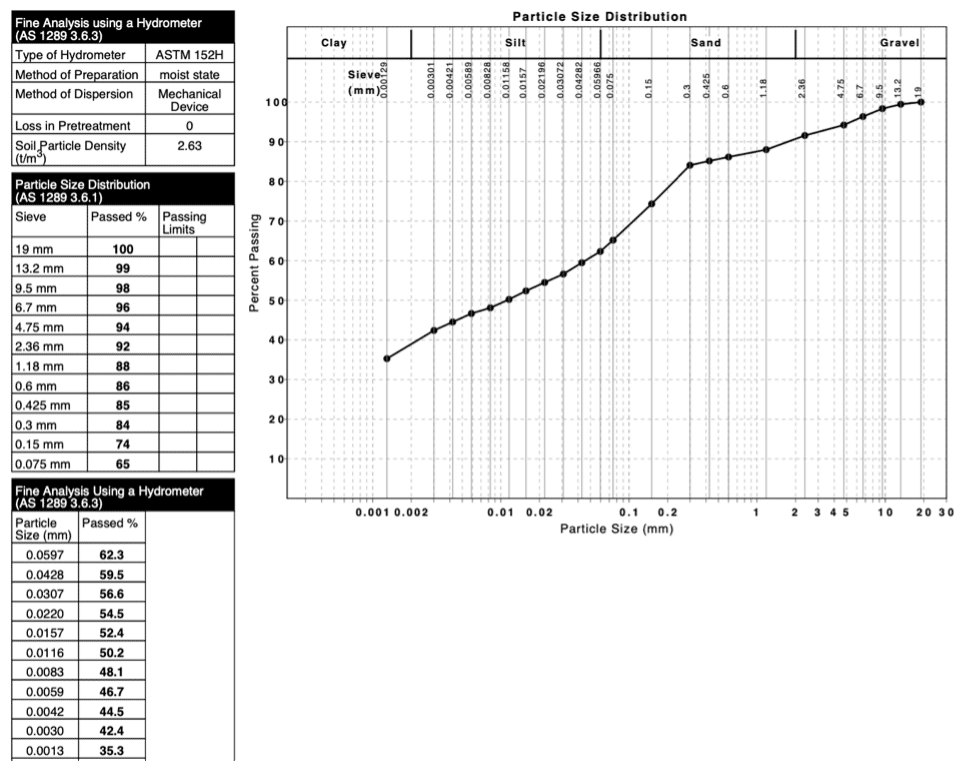

We assist clients to determine the suitability and performance outcomes using TERRA-3000® for each particular project. A sound starting point is to perform Particle Size Distribution (PSD) and Hydrometer tests. The hydrometer test quantifies the clay and silt fractions within the candidate materials.

A model particle distribution has an even particle distribution range between 0.002 mm and 37.5mm. Larger fractions (> 50 mm) are crushed prior to treatment.

However, TERRA-3000® can be used to successfully treat a wide range of soil profiles with varying clay contents.

Applications

TERRA-3000® is suitable for a variety of stabilisation applications.

Pavement applications include:

- New Construction and Rehabilitation

- Pavement maintenance including heavy patching

- End of life pavement recycling

- Sustainable alternative to aggregate sheeting

- Water / flood resilience, erosion control, drainage

- Roads including:

- Mine haul roads (above and below ground)

- Service roads and access tracks

- Road shoulders to protect from moisture ingress

- Parking areas

- Rail (track beds and formations)

- Airports (runways, taxiways and aprons)

- High availability / disaster recover / on demand infrastructure – roads, hardstands, airstrips

- Hardstands (port, loading areas etc)

Other applications include:

- Temporary works platforms

- Dams, dykes, levees and canals:

- including dam wall raises

- seepage control / containment to contain the flow of water and to minimise erosion

- Land development

- Defence

TERRA-3000® is suitable and safe to use in environmentally sensitive areas such as near rivers and lakes.

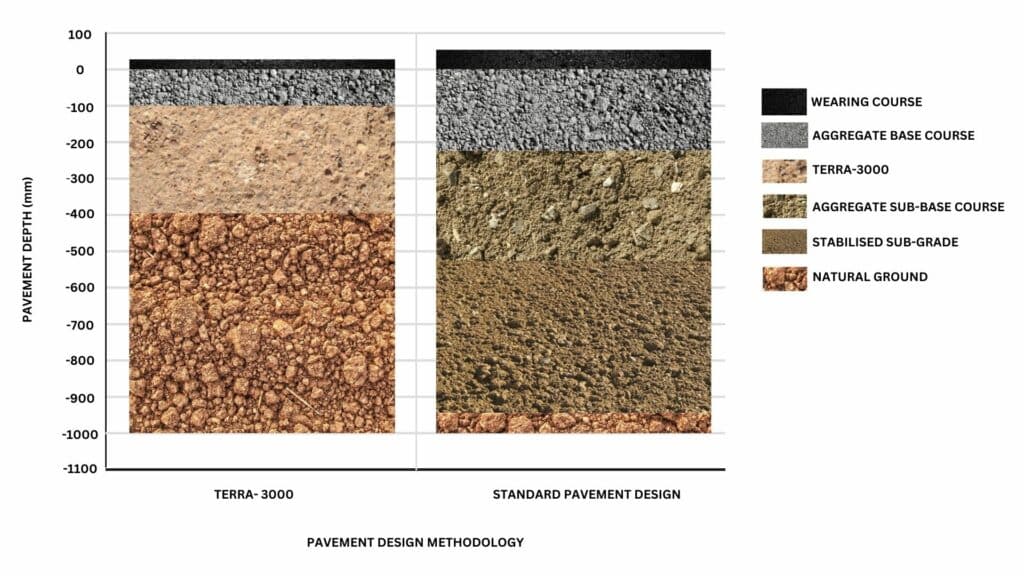

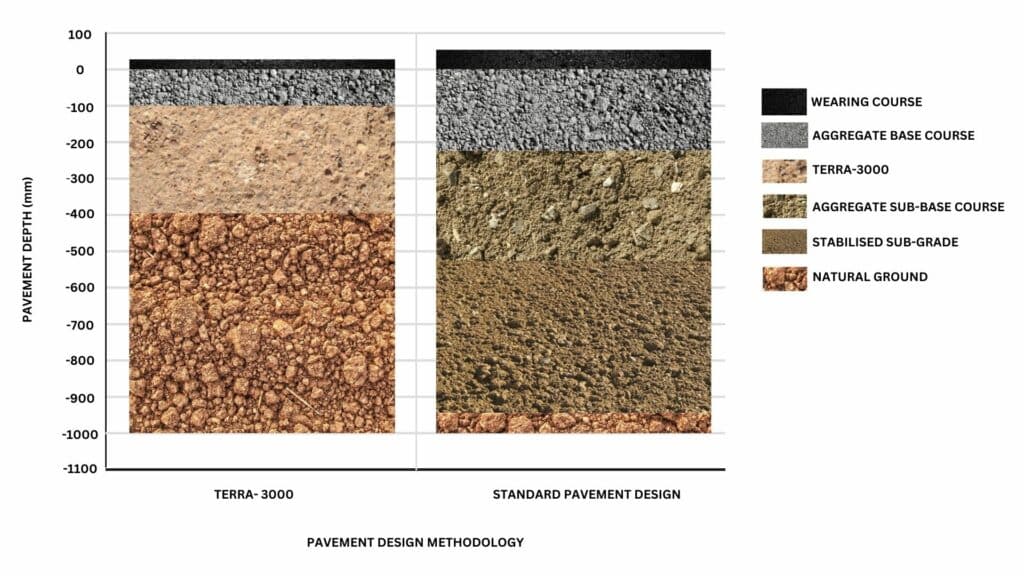

Pavement Design

The use of TERRA-3000® to improve the mechanical and hydraulic performance of in-situ soils has a profound impact on traditional pavement design. The diagram below gives an indication of the reductions in pavement depth and thickness in wearing course made possible by stabilisation of in-situ soils using TERRA-3000®.

Our best practice approach to support maximum savings in construction cost and the most sustainable outcomes, features a single high performing base-grade layer treated with TERRA-3000®. That said, TERRA-3000® treated layers can be targeted to both complement or supplement traditional pavement designs.

Treatment & Testing

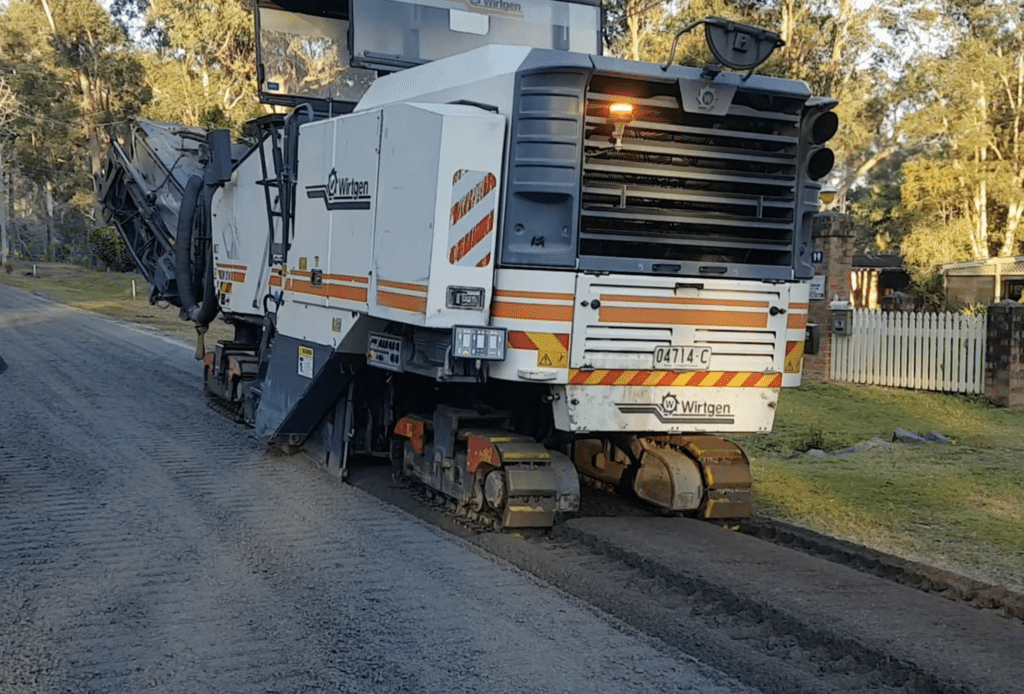

Pavement construction with TERRA-3000® uses typical civil construction equipment. Ideal application equipment includes:

- a mechanical stabiliser enables a uniform rate of application and thorough mixing

- a heavy multi-tyre roller for the best compaction outcome

TERRA-3000® is a liquid concentrate that is diluted with water during treatment at a typical rate of 1:20.

- Treatment is as simple as:

- Rip

- Apply

- Mix

- Shape

- Compact

Insitu materials are loosened (rip) and brought to optimal moisture content (OMC) with the addition of water, or in damp settings, allowed to aerate until optimal moisture content is reached. Diluted TERRA-3000® is evenly applied either with a mechanical stabiliser (apply and mix) or using a water cart and thoroughly mixed by grader blade. Treated materials are then shaped and compacted using predominately static compaction (shape and compact).

We train civil construction crews on the application of TERRA-3000® using their own construction equipment.

TERRA-3000® is safe to use, both for those applying it and for the environment. Adhere to the instructions contained in the Material Safety Data Sheet (MSDS) and product labelling. For easy handling, TERRA-3000® is supplied in 1 litre bottles, 25 litre containers and 1,000 litre intermediate bulk containers (IBC’s).

Immediate performance feedback (through insitu tests) and adjustment is possible during construction. Suitable insitu testing methods include the Light Weight Deflectometer (LWD) and Plate Load Test (PLT).

TERRA-3000® requires the presence of clay and silt fines to improve the mechanical and hydraulic performance of soil. It is suitable and safe to use in environmentally sensitive areas such as rivers and lakes. It doesn’t leach and leaves no reside.

TERRA-3000® requires the presence of clay and silt fines to improve the mechanical and hydraulic performance of soil. It is suitable and safe to use in environmentally sensitive areas such as rivers and lakes. It doesn’t leach and leaves no reside.