MIT SCAN-T3 Asphalt and Concrete Thickness Test

- Non-destructive test (NDT) for asphalt thickness and concrete thickness for pavements

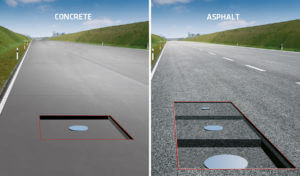

- Full depth or layer by layer thickness measurement for asphalt, concrete and unbound material

- Accuracy of the MIT SCAN is ± (0.5% of measured thickness + 1mm).

- Meets ASTM E3209 / E3209M – 20 and EN 12697-36:2003 (Hot Mix Asphalt – HMA) standard

Applications

The consistent application of a required depth of concrete, asphalt or unbound material for pavements is important to road construction contractors and their clients, the road authorities and councils who need to verify that the asphalt or concrete has been laid to the required pavement thickness. The MIT-SCAN-T3 enables you to perform this task efficiently.

This test is only suitable for construction where reflectors can be inserted into the pavement.

The MIT SCAN-T3 can be used directly after the application and rolling of hot asphalt. This means that it can be used to measure partial layer thickness to ascertain exactly how much material is required to bring the pavement thickness up to the final required level. It can also be used on milled surfaces.

The MIT-SCAN-T3 can also be used immediately after concrete has been laid. As soon as you can walk on the concrete, you can measure the concrete thickness.

The MIT-SCAN-T3 from MIT Mess- und Prüftechnik using Magnetic Imaging Tomography technique (MIT), a technique which uses reflectors inserted into the pavement during construction, according to ASTM E3209 / E3209M – 20 and EN 12697-36:2003 (Hot Mix Asphalt – HMA).

Advantages

The accuracy of the MIT SCAN of ± (0.5% of measured thickness + 1mm) compares favourably with surveying or coring. The equipment compensates for changing environmental conditions. This includes wet road surfaces or magnetic aggregates.

Other advantages of the MIT-SCAN-T3 include:

- Non-destructive measurement (NDT) so reduces or eliminates coring

- GPS-System to immediately determine and record your position integrated with Google Maps

- Fast and repeatable

- Easy data management for storage, presentation and geo-positioning using the PC-based software

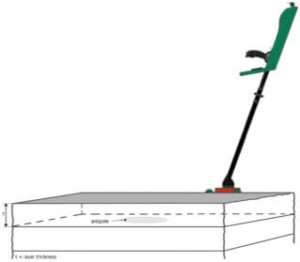

- Light, hand held device, take-apart for transport

- No impact from wet road surfaces or magnetic aggregates

- Common reflectors allow measurements from 15mm up to 500 depths

- Only rough location of reflectors required before measurement

- Measurements possible on steel reinforced bridges

- Calibration for customer specific reflectors possible

- Can be integrated into automatic reflector laying and thickness measurement systems

Here you will find more detail about how the equipment works in practice.

MIT-SCAN-T3 Calibration, Service and Spare Parts

Insitutek are proud to represent MIT Mess- und Prüftechnik MIT-SCAN-T3 in Australia, New Zealand and the Pacific Islands and provide a high level of client support.

We offer a complete spectrum of services including after-sale technical support, servicing, repairs, and calibrations.

To find out more, Contact Us.

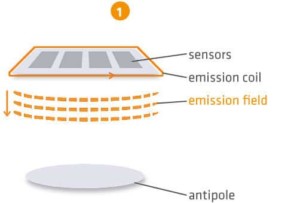

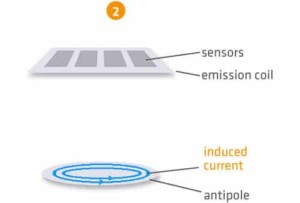

It uses Magnetic Imaging Tomography (MIT), a technique based on pulse induction technology which uses reflectors inserted into the pavement during construction.

It uses Magnetic Imaging Tomography (MIT), a technique based on pulse induction technology which uses reflectors inserted into the pavement during construction. The pulse induction technology leads to a high noise immunity and a wide measurement range. Probe head and electronic housing are connected through a take-apart central pipe.

The pulse induction technology leads to a high noise immunity and a wide measurement range. Probe head and electronic housing are connected through a take-apart central pipe.