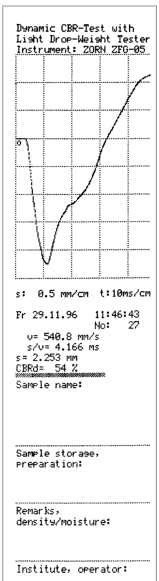

Dynamic CBR Test with Light Weight Deflectometer (LWD)

- Measures California Bearing Ratio (CBR) directly in the field

- Penetration test

- Evaluate the mechanical strength of subgrades and base courses

- Immediate repeatable results so that on-site decisions can be made straight away

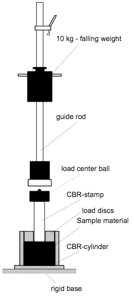

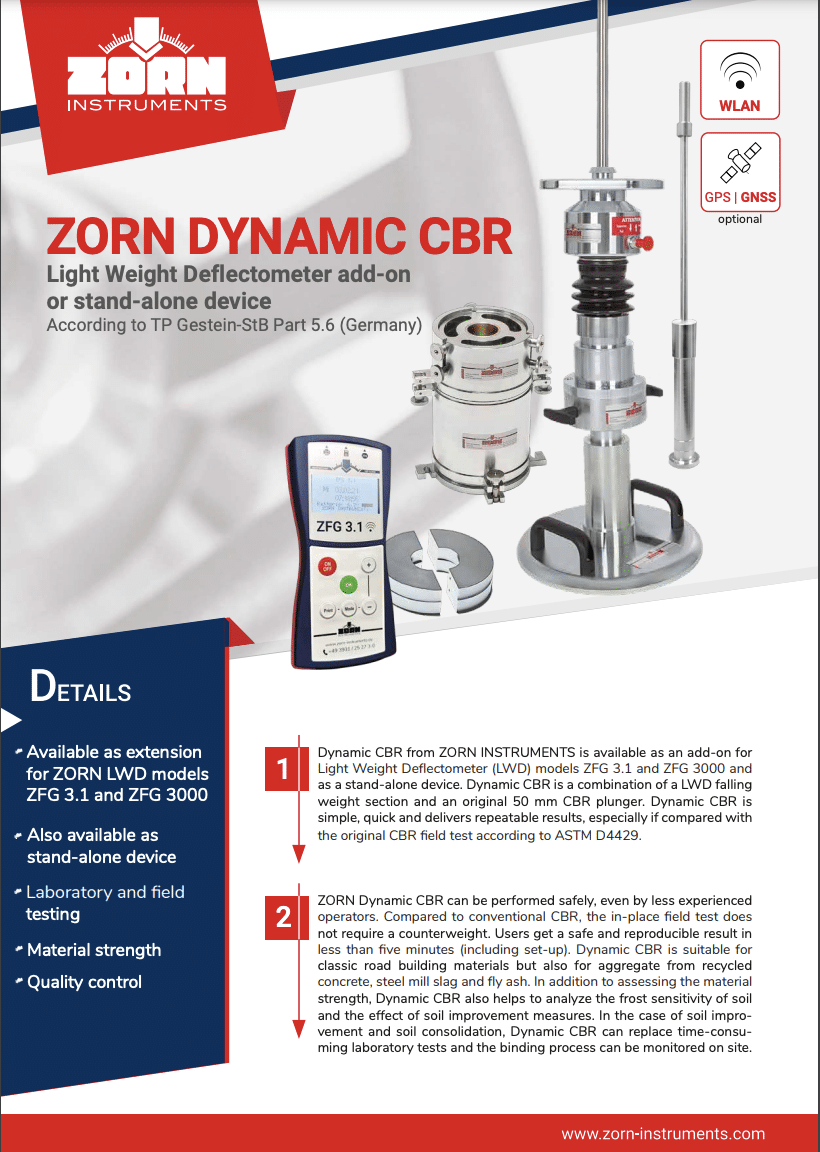

Using extensions to the Light Weight Deflectometer, dynamic CBR (California Bearing Ratio) is measured in-situ and also laboratory CBR in a cylinder can be simulated at the construction site. It can be used in confined spaces and difficult to access locations, with no support equipment required.

Two CBR test options are available:

|

|

| Insitu CBR Extension | Portable Laboratory CBR Extension |

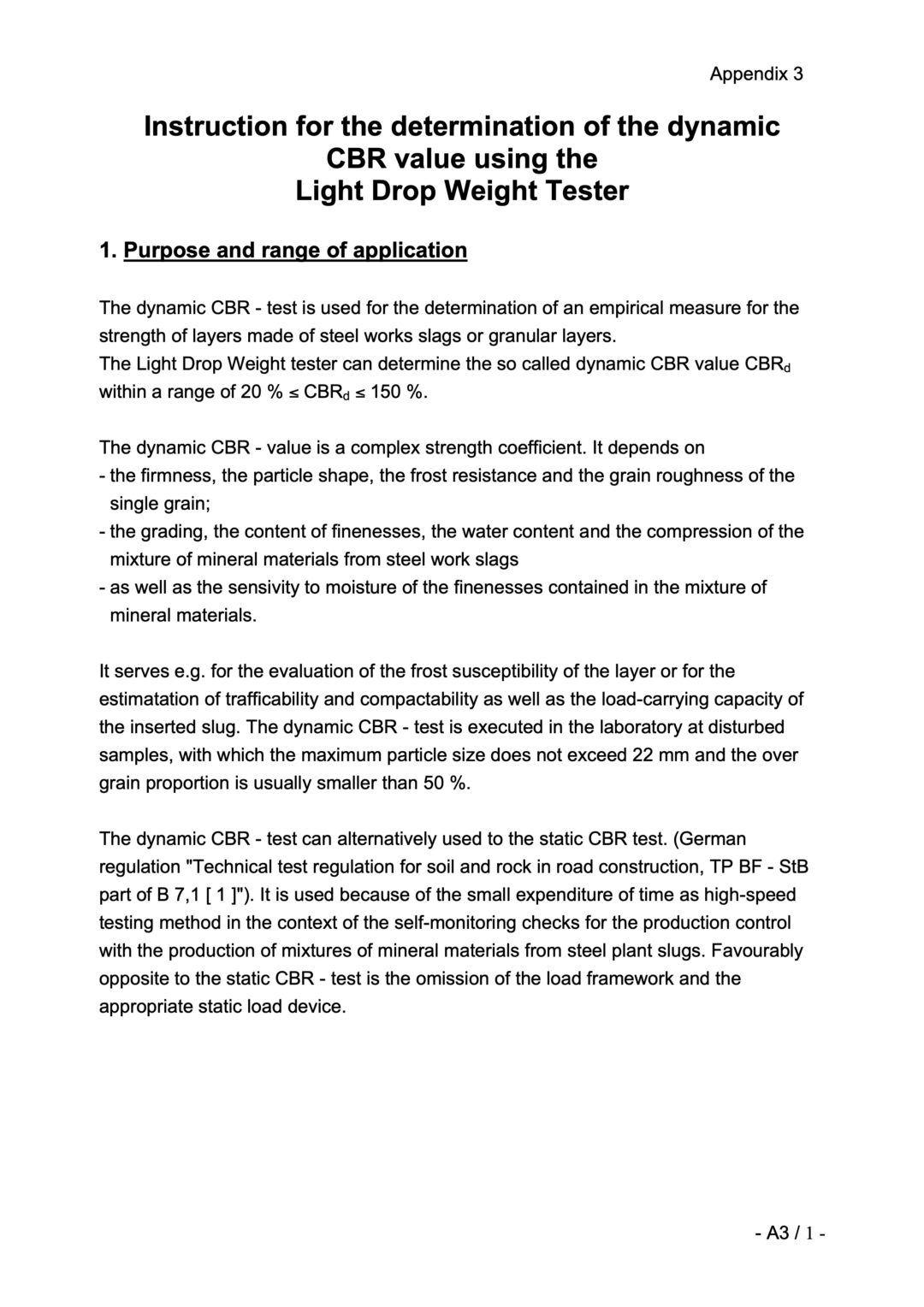

California Bearing Ratio (CBR) is a simple penetration test developed to measuring the load-bearing capacity of soils for road subgrade and base courses used for building roads, airport runways or railway track beds. The dynamic CBR test, in particular the in-situ field test, is a material test on undisturbed samples, with which one can judge what level of compaction can be achieved on the tested soil.

The Dynamic CBR Extensions together with the ZFG 3000 Light Weight Deflectometer can be used instead of the static CBR test and is used primarily because of the ability of get immediate results on site.

Advantages

Advantages of the CBR field extension include:

- Measurement takes only three minutes per test location.

- All readings and analysis can be done in the field and the results are immediately available at the construction site.

- The equipment is portable and no counter weight or truck mounting is required.

- Measurements are possible in narrow situations including ditches and foundation trenches, back fill, core holes or other areas that are difficult to reach.

- Adherence to TP BF – StB Part B 7.1, removing the need for a load frame and the static load device (compression test). In its place, a loading device according to TP BF – StB Part B 8.3 is used.

Light Weight Deflectometer (LWD) Calibration, Service and Spare Parts

Insitutek are proud to represent Zorn Instruments Light Weight Deflectometers (LWD’s) in Australia, New Zealand and the Pacific Islands and provide a very high level of client support.

We offer a complete spectrum of services including after-sale technical support, servicing, repairs, and calibrations. Our clients have exclusive access to the only Light Weight Deflectometer calibration and service cwntre in the Southern Hemisphere. Run by Zorn Instruments trained technicians, our service centre is also well stocked with spare parts. Our Australian based Zorn Instruments Calibration Stand and Service Centre is exclusive to Zorn clients and saves you significant down time compared to calibration and repairs overseas.

To find out more, Contact Us.