Cone Penetration Testing (CPT)

- Used for site characterisation and soil sampling

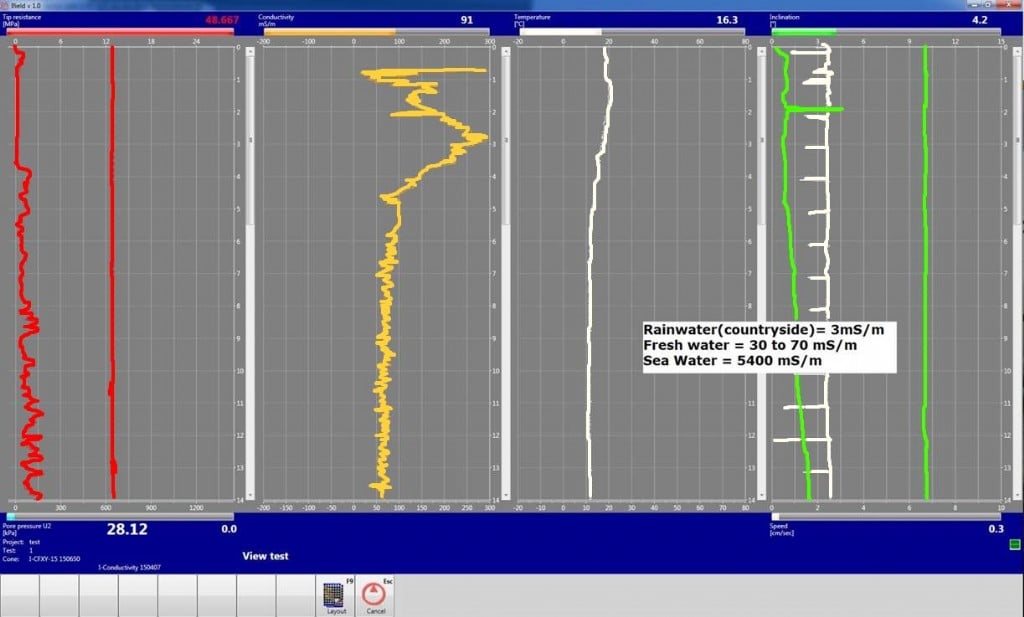

- Digital CPT piezocones to measure cone tip resistance (qc), sleeve friction (fs), pore water pressure (u) & inclination (Ix/y)

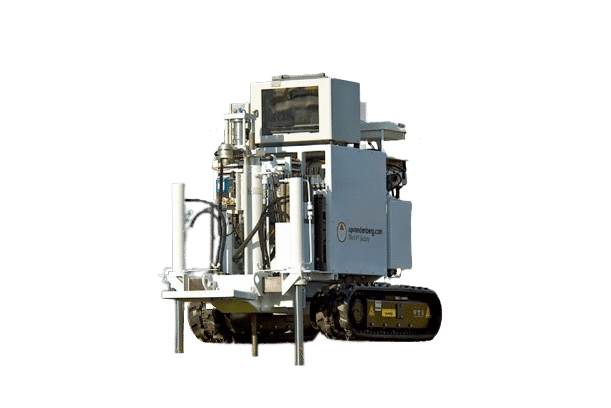

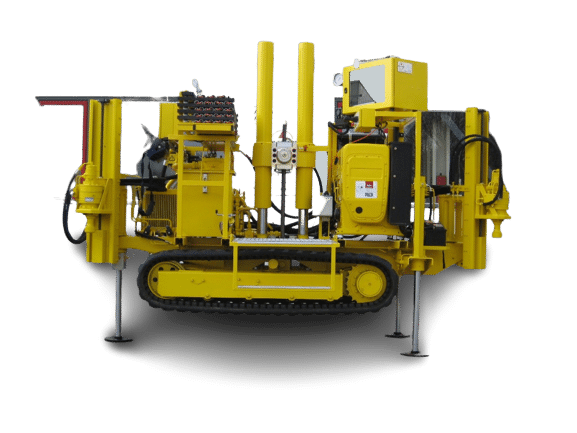

- Range of rigs from portable lightweight skids to crawler and truck mounted

- Click on modules for down hole shear vane, seismic, conductivity and magneto

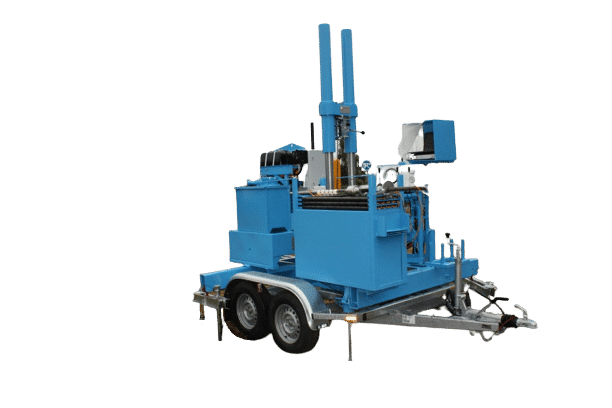

Insitutek have partnered with renowned Dutch Cone Penetration Testing (CPT) equipment manufacturer, A.P. van den Berg, and we represent them in the Pacific Region including in Australia and New Zealand. For more than 50 years, A.P. van den Berg has designed and manufactured advanced CPT equipment and is well-known for their innovations and robust high quality equipment. A.P. van den Berg supplies complete or partial systems including the pushing equipment, tools and data acquisition systems. Our Cone Penetration Testing rigs use hydraulic rams to push 36 mm diameter rods into the soil from either a ballasted truck, ballasted track-truck, ballasted or anchored crawler, anchored trailer or anchored portable skids.

Applications

CPT is a rapidly developing site investigation technique with a wide range of applications, including:

- Geotechnical: CPT provides information on the soil profile, which can be used to design foundations, provide quality control for ground improvement work or to check the condition of a levee or a dike, for example.

- Hydrogeological: to analyse the level and flow of groundwater or the interaction between groundwater and the surrounding soil.

- Geo-environmental: to check the length of unknown foundations or the presence of buried steel objects, but also to determine the presence of contaminants in the soil.

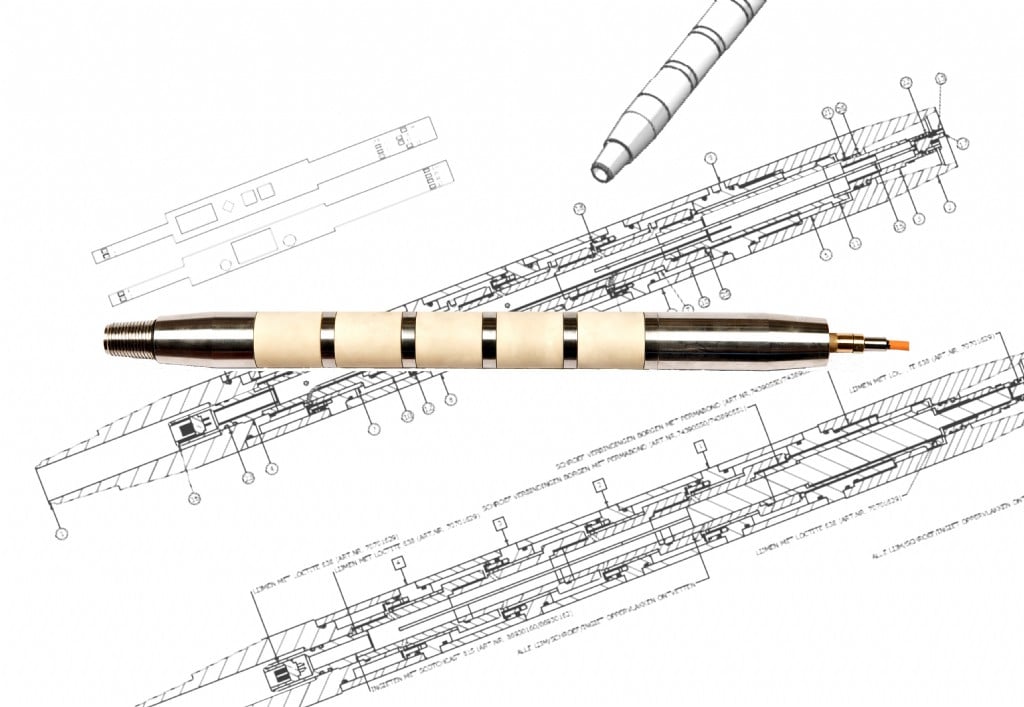

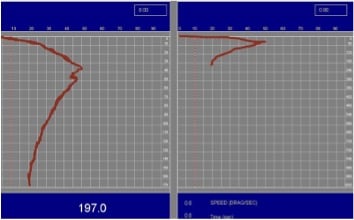

To obtain detailed and accurate geotechnical properties of soils, A.P. van den Berg developed the Icone, a digital CPT piezocone, and Icontrol, a digital data logger. The Icone measures the four standard CPT parameters:

- cone tip resistance (qc)

- sleeve friction (fs)

- pore water pressure (u)

- inclination (Ix/y)

Cone tip areas range from 5cm2 – 15cm2.

Click-On Modules for Down Hole Electrical Shear Vane Testing (EVST), Seismic CPT (SCPT), Conductivity and Magneto

The demand to build a comprehensive and accurate picture of the subsoil by using additional parameters from in-situ soil investigation is increasing. For example it may be required to derive the in-situ properties of both soil stratigraphy and soil elasticity to design a foundation that is subject to vibration; or both the soil density and soil electrical conductivity to determine contaminated layers and predict future distribution.

By having each module attached to a CPT or CPT(u) cone, our digital CPT data acquisition system allows simultaneous acquisition of CPT / CPT(u) data and module data. All modules can be used with a 10 cm2 and a 15 cm2 Icone. When CPT-data are not required, the click-on modules can also be used with a dummy tip instead.

Using click-on plug & play modules, additional parameters can be collected:

Icone Vane (downhole Electrical Vane Shear Test (VST)

- Soil investigation in soft soils, like clay, silt and mine tailings

- Allows in-situ measurement of the peak, residual and remoulded undrained shear strength

- Electric motor drive and torque measurement are at the bottom of the rods, just above the vane, significantly improving results integrity by minimising friction

The A.P. van den Berg Icone Vane (Electrical Vane Shear Test (VST)) is unique in the fact that the electric motor drive and torque measurement are at the bottom of the rods, just above the vane, significantly improving results integrity by minimising friction. This eliminates the need for a slip joint or any other form of rod friction correction, as there is no rod friction. This is particularly important in jobs with very soft conditions where friction corrections can “swamp” the vane torque readings, making outcomes less reliable.

The Vane Shear Test (VST) equipment consists of a four-blade, stainless steel vane attached to a steel rod that will be pushed into the ground. The Icone Vane can be supplied with several blades sizes. The blade size is generally selected depending on the anticipated peak undrained shear strength at the target depth. To prevent damage, the drive motor and torque assembly are preconfigured to apply a maximum torque of 100 Nm.

The A.P. van den Berg computer controlled harmonic drive system on the torque motor allows the rotation rate for testing to be selected within the range of each of the three models.

- Icone Vane Slow – adjustable rotation speed of 0.1 to 6° per second for very accurate shear tests – 90% of clients go for this

- Icone Vane Fast – adjustable rotation speed of 0.2 to 12° per second for fast remoulding of the soil in situations with a low shear value.

- Icone Vane HS (High speed) – in soft mine tailings, an adjustable rotation speed of 1 to 60° per second can provide sufficient reactive force/torque and therefore improved determination of the drained and undrained shear strength, resulting in more reliable stability analyses of mine tailings.

For example, with the slow model, a rotation speed of 0.1 degrees/second is used to measure the peak undrained shear strength e.g. in clays and a higher rate, of up to 6 degrees/second, is used for remoulding followed by measuring the residual undrained shear strength at the lower rotation speed.

The Icone Vane is also available in protected or unprotected formats:

- unprotected is suited for pre drilled holes or soft material

- protected protects the vane from damage during pushing using a protection shoe. It is suited to pushing through stiffer materials, like embankments. The protected format increases the rate of production as it allows completion of various Electrical Vane Shear Tests (EVST’s) at different depths and eliminates drill outs and pulling out the equipment assembly between tests.

The unprotected format Icone Vane uses standard 36mm CPT rods to push the vane down.

The protected Icone Vane uses standard 36mm CPT rods to hold the vane and 56mm casing tubes are used to hold the protection shoe.

Once the desired depth is reached, the vane blades are advanced and testing can begin.

Icone Seismic Module for Seismic CPT(u)

- Predict ground stability responses (e.g. settlement, liquefaction and failure) to imposed loads like foundations, vibrating equipment (e.g. around excavations), earthquakes, trains travelling at high speeds or explosions.

- Measuring the propagation speed of sound using seismic CPT (SCPT), together with the soil density (usually already known), enables calculation of:

- small strain shear modulus & constrained modulus

- elasticity modulus

- Poisson’s ratio

- Determine the depth of regional or perched water tables

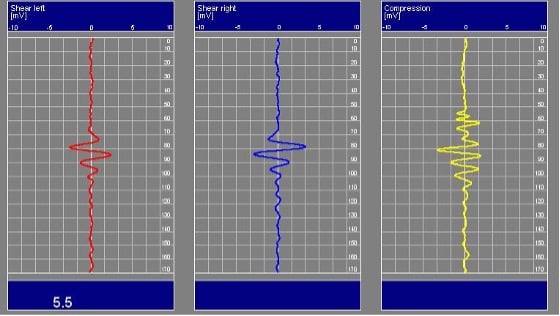

The Seismic CPT acquisition is conducted with the seismic module attached to a CPT(u) cone allowing simultaneous acquisition of CPT(u) data and seismic data. It is designed such that the seismic sensor records the soil profile’s response to low strain seismic disturbances.

A.P. van den Berg’s Seismic Cone Pentration Test (SCPT & SCPTu) system adds measurement of both compression and shear wave velocities (Vp, Vs) to the parameters obtained with CPTu (cone tip resistance, sleeve friction and pore pressure).

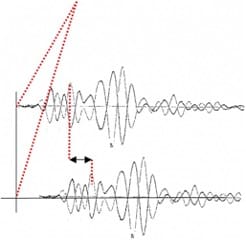

Elastic soil parameters are determined by measuring the propagation speed of an applied sound wave between two known depths. The seismic module is pushed into the soil while stopping at 1 metre intervals. During the pause in penetration, an shear wave (S wave) or compression wave (P wave) is generated by applying a hammer blow laterally to the end of the hammer beam fixed to the CPT rig and the time required for the wave to reach the seismic sensor is recorded. The time difference between two consecutive seismic tests is a measure for the elastic properties of the soil.

The Icone Seismic Module does this using 3 accelerometers (20Hz – 300Hz) to receive left and right shear waves (S Wave ) as well as compression waves (P Wave).

To increase the speed or accuracy, it is possible to measure at two or even more depths simultaneously by using extra seismic modules, mounted at fixed distances of 0.5 or 1 metres. Furthermore seismic signals from one depth can be stacked in the Ifield software, in order to improve the seismic signal by averaging out the noise.

The Icone Seismic Module is a plug & play extension to the digital Icone data acquisition system and is automatically recognized by Ifield software and Icontrol datalogger. It can be combined with 5, 10 and 15 cm2 Icones or other click-on modules.

When CPT data are not required, the click-on modules can also be used with a dummy tip instead.

Icone Conductivity Module

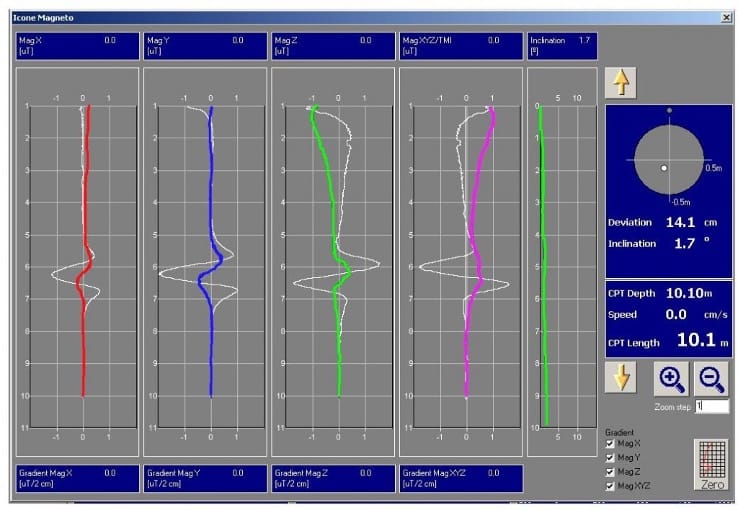

Icone Magneto Module

• 3-dimensional detection of the magnetic field

• detection of sheet piling, ground anchors and Unexploded ordnance (UXO)

Icone Magneto Module detects objects in the soil containing magnetisable metal, e.g. unexploded ordnance (UXO), ground anchors, piping, the tip of sheet piles and foundation piles by interpreting anomalies of the earth’s magnetic field.

The Magneto Module is equipped with its own inclinometer in X- and Y-direction, to allow for accurate positioning.

Anomalies can be detected at a distance up to 2 m depending on the size of the object. To accurately respond to changes in the measured value, in particular when detecting UXO’s, the gradients of the orthogonal measured anomalies are also determined. Alarm values can be set to stop pushing when one of these gradients is exceeded.

Undisturbed soil sampling using MOSTAP sampler

Almost undisturbed soil samples can be rapidly collected with the use of A.P. van den Berg’s MOSTAP sampler. Continuous core sampling can be performed in runs up to 1.0 m or by discrete sampling at any depth. Samples are typically contained in 65mm diameter plastic liners to minimise disturbance in collection and transit.

Cone Penetration Test (CPT) Sales, Calibration, Service and Spare Parts

Insitutek are proud to represent A.P. van den Berg Cone Penetration Test (CPT) equipment in Australia, New Zealand and the Pacific Islands. We provide a high level of client support, from technical pre-sale consultations and supply of equipment to commissioning, user training, after-sale technical support, servicing, repairs, and calibrations. Our service centre is also well stocked with spare parts and consumables.

To find out more, Contact Us.

What is Cone Penetration Testing?

Cone Penetration Testing (CPT) uses a cylindrical instrumented cone pushed vertically into the ground at a constant rate of penetration of 2 cm/sec to identify subsurface conditions down to 40m or more, depending on the pushing equipment and soil conditions. The collected data allows reliable interpretation of soil strength and stiffness parameters, and the soil type.

Cone Penetration Testing uses hydraulic rams to push 36 mm diameter rods into the soil from a ballasted truck, ballasted track-truck, ballasted or anchored crawler, anchored trailer or anchored portable skids.

A CPT conducted to a depth of 25 m will take about 2 hours. This is much quicker, and therefore cheaper, than drilling, which may take a day or more and would not provide the same level of detailed useful subsurface information.

Cone Penetration Testing (CPT) is a sophisticated Dutch soil investigation technique. For more than 50 years, A.P. van den Berg has designed and manufactured advanced CPT equipment and is well-known for its innovative strength and robust high quality equipment. A.P. van den Berg supplies complete or partial systems including the pushing equipment, tools and data acquisition systems.

In situations where the CPT is unsuitable (e.g. course gravels up to 150mm), the GRIZZLY® Dynamic Probing Super Heavy (DPSH) is a suitable alternative, benefitting from dynamic energy to penetrate stiff and very stiff materials.