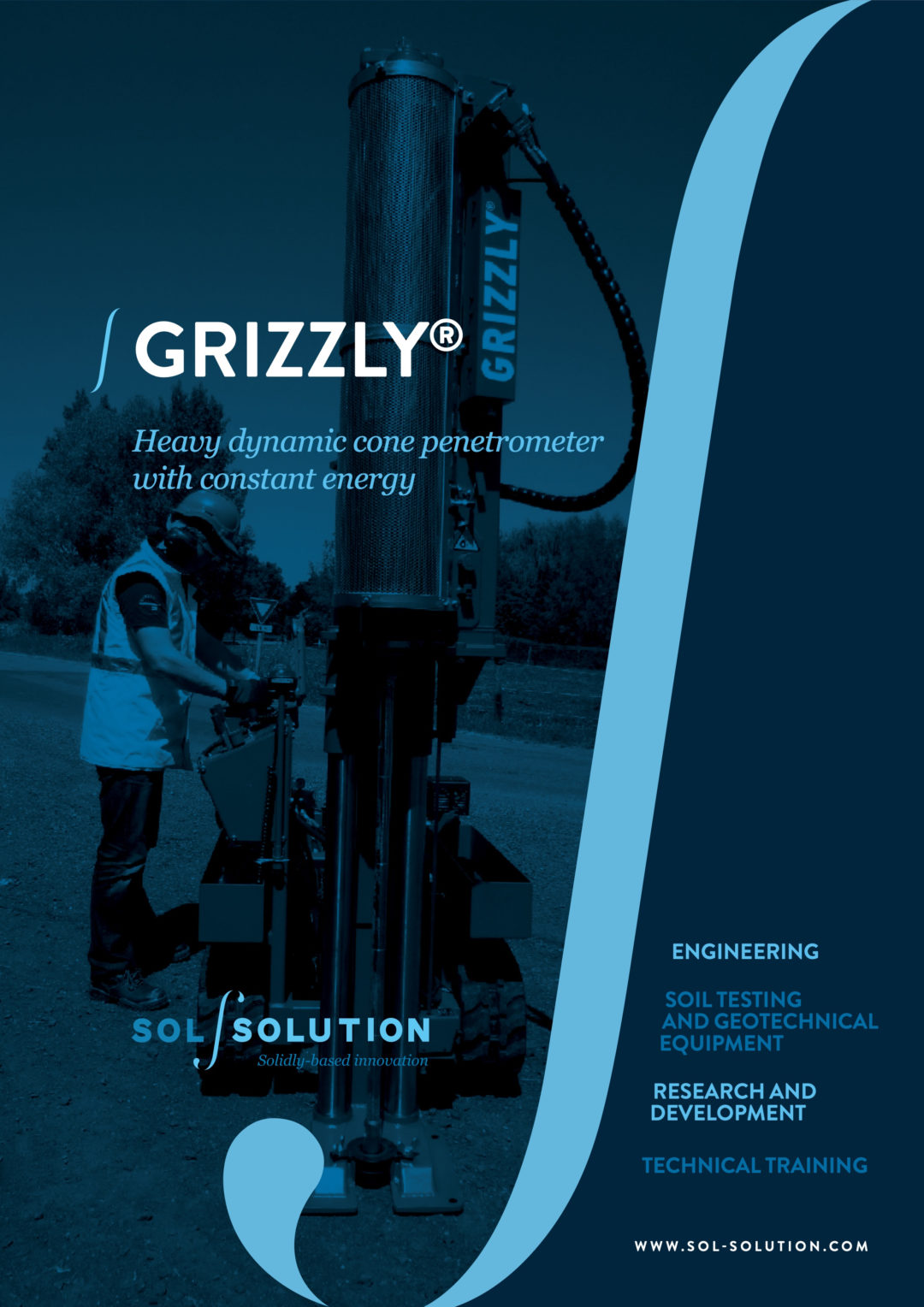

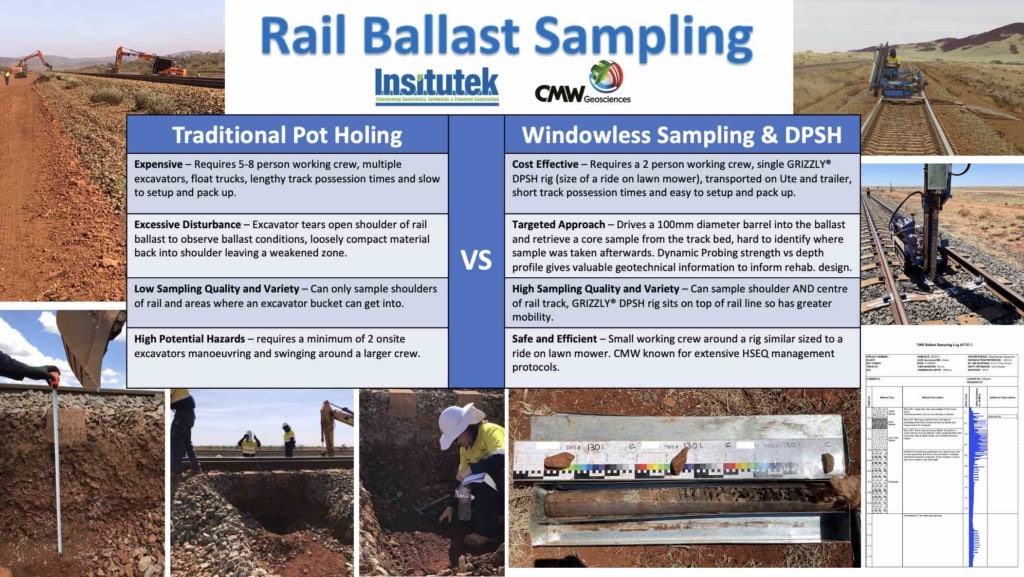

- Self propelled Dynamic Probing Super Heavy (DPSH) rig with geotechnical drilling capability

- Used for compaction control, site investigation, geotechnical drilling and soil sampling (windowless push tube sampling and Standard Penetration Test (SPT) split spoon sampling) for chemical and geotechnical analysis

- Immediate repeatable results so that on-site decisions can be made straight away

- Meets NF P94-063 and EN ISO 22476-2 standards.

The GRIZZLY® Instrumented Dynamic Probing Super Heavy (DPSH) is a constant energy heavyweight dynamic cone penetrometer is used to measure the in-situ strength of fine- grained and granular subgrades, base and sub base materials, and weakly cemented materials.

Depths of 10-15m or more can be achieved, depending on the soil type.

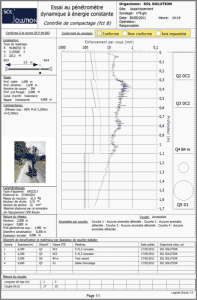

Using the data acquisition system, results can be presented as:

- Depth per blow (mm/blow)

- Cone resistance (MPa)

- N10 or N20

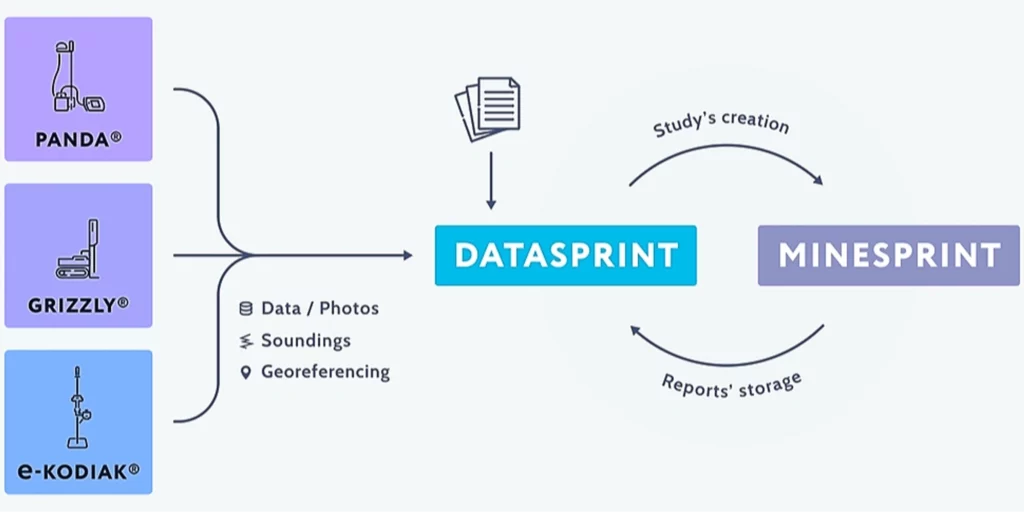

GRIZZLY® data is downloaded to WebSprint©, the cloud based software for securely storing, processing and interpreting your geotechnical data. WebSprint© facilitates easy collaboration across your team. WebSprint© gives you access to compaction control, soil investigation and correlations modules.

Soil Investigation

Site characterisation is unarguably the most important, but also most “difficult”, component of geo-engineering. The GRIZZLY® is designed to improve the quality of site characterisation and reduce the difficulties involved.

The GRIZZLY® meets EN ISO 22476-2 – Geotechnical engineering – Field testing – Part 2: Dynamic probing – DPSH-B.

The GRIZZLY® DPSH compares favourably with Cone Penetration Test (CPT) because it can test in materials that you cannot test with a CPT (e.g. course gravels up to 150mm) and does not have high cost wearing parts (like CPT sensors and their calibration).

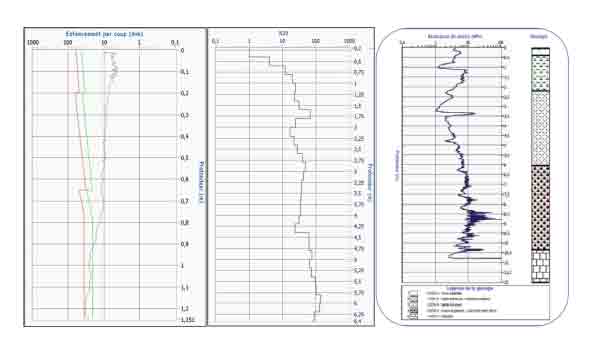

A geological profile (database available) can be associated with the penetrogram, giving a pictorial representation of the geology and stiffness of the ground.

In a world first, the Variable Energy option converts the GRIZZLY® from a constant dynamic energy penetrometer (DPSH) into a Variable Energy version, providing high resolution, reliability and accurate measurements in softer soils by automatically adapting to the resistance of the soils encountered during the test. Hence with the Variable Energy option, the GRIZZLY® DPSH is very good at measuring the interface between hard and soft zones which are of great interest to geotechnical engineers.

Attachments available include a geotechnical drilling head and auger (diameter 63 mm) for soil investigation at depth and soil sampling attachments (windowless push tube sampling and Standard Penetration Test (SPT) split spoon sampling) for chemical and geotechnical analysis.

Being light and compact, the GRIZZLY® is particularly good for testing in challenging conditions (difficult to access locations or confined spaces).

Compaction Control

The GRIZZLY® is used to monitoring layer thickness, and to assess compaction homogeneity. It’s also used for layer identification.

Now you can see real time when doing the test if your material meets the compaction specification or not.

An integrated compaction control database for various soil types is used where the measurement of the driving depth (mm) and cone tip resistance (qd) is compared to a database based on the type of soil (soil classification), its water content and the required compaction quality (%OPN or OPM).

The related pre-calibrated reference and refusal lines, when compared to the test data, allow an assessment of the quality of the compaction to be made. The database is catalogued in terms of plasticity, grain size distribution, water content, and level of compaction for both natural and artificial (crushed gravels) material types. Anomalies calculation is done automatically with the embedded GRIZZLYWIN software.

The GRIZZLY® DPSH meets NF P94-063 – Compaction quality control – Constant energy dynamic penetrometer method.

GRIZZLY® Options – Variable Energy, Geotechnical Drilling, Soil Sampling, Torque Measurement

The options for the GRIZZLY® Dynamic Probing Super Heavy (DPSH) include:

- Variable Energy option which converts the GRIZZLY® from a constant dynamic energy penetrometer (DPSH) into a Variable Energy version, providing high resolution, reliability and accurate measurements in soft or very soft soils whilst automatically adapting to the resistance of the soils encountered during the test.

- Geotechnical drilling head with Auger (diameter 63 mm) for geotechnical drilling and soil investigation at depth.

- Windowless push tube sampling

- Standard Penetration Test (SPT) split spoon sampling (meets AS 1289.6.3.1 and EN ISO 22476-3).

- Torque measurement using a torque wrench to control excessive lateral friction between soil and the rod.

Variable Energy Option

Traditional DPSH rigs are most suited to deep tests and when medium to very high consistency layers are present. The DPSH is particularly suitable for soils having a cone resistance value from 3 to 60 MPa (SPT blow number equivalent: 6 < N < 100). It is not recommended for the characterization of loose, soft soil and/or saturated sands, silts and clays. In very soft soils, one blow can result in the tip of the cone penetrating into the soil 200 mm or even more, resulting in loss of resolution, reliability and accuracy. However, these soft soil strata are of particular interest to geotechnical engineers and reliable measurements are necessary in order to accurately characterize them.

Sol Solution has succeeded in solving this problem, enabling a heavy dynamic penetrometer to provide fine measurements in soft or very soft soils and to automatically adapt to the resistance of the soils encountered during the test. The Variable Energy option converts the GRIZZLY® from a constant dynamic energy penetrometer (DPSH) into a Variable Energy version.

The GRIZZLY® is the first in the world to offer this performance with full automation.

The Variable Energy GRIZZLY® is equipped with a series of sensors and electromagnetic systems to provide multiple energies (DPL, DPM, DPH and DPSH) by varying the drop height whilst maintaining the same hammering mass.

The on-board computer adjusts the driving energy for each blow by modifying the drop height of the mass based on the penetration of the previous blow. Hence, maintaining a constant energy/settlement ratio throughout the test. The drive energy is adjusted for each blow and it is based on variations of the drop height of the mass controlled automatically by the on-board computer.

Adjustments to the driving energy are applied to achieve a penetration per blow between 2 to 20 mm. The more variations of soils resistance there are, the more frequent will be the energy changes. No intervention of the operator is required during the test.

The Variable Energy GRIZZLY® has 4 different drops heights that correspond to the EN ISO 22476-2 standard for all the Dynamic Probing (DP) configurations (DPL, DPM, DPH, DPSH energy).

| Light DPL | Medium DPM | Heavy DPH | Super Heavy DPSH | |

| Drop Height | 160mm | 320mm | 540mm | 760mm |

You can set-up the GRIZZLY® in automatic:

- Define a penetration minimum

- Define a penetration maximum

- Start the test with minimum energy

- If the penetration is between these 2 values, it doesn’t change anything

- If the penetration is smaller than the minimum value, it will increase the falling height to the next height

- If the penetration is bigger than the maximum value, it will reduce the falling height to the previous height

Alternatively, you can choose to work in manual mode, and define manually the falling heights.

Geotechnical Drilling Head

The geotechnical drilling head is a fully integrated attachment that allows the GRIZZLY® to be turned immediately from a Dynamic Probing Super Heavy (DPSH) into a geotechnical drilling rig with a 63mm helical auger suitable for soil investigation. Depths of 10-15m or more can be achieved, depending on the soil type.

- Drilling auger max. rpm – 150 rpm

- Drilling auger max. torque – 100 kg.m (98.1daN.m)

Applications include helical auger drilling, soil sampling for geological profiling and environmental analysis, pressumeter tests and the Standard Penetration Test (SPT).

Windowless Push Tube Sampling

Windowless push tube sampling is a technique used to bore through shallow soft soils to investigate the substrata in order to gain a profile of the ground conditions and to facilitate soil sampling for chemical and geotechnical analysis. Windowless push tube sampling can be used for the investigation of contaminated land, for geotechnical investigations and for the installation of ground gas and ground water monitoring wells.

Using the GRIZZLY DPSH capability, push tube sampling enables the collection of partially disturbed samples with minimal site disturbance. It’s a windowless sampler (with plastic liner) and, typically, depths of up to 5m can typically be achieved.

Standard Penetration Test (SPT) Split Spoon Sampling

The Standard Penetration Test (SPT) split spoon sampling tube is an additional feature of the GRIZZLY® Dynamic Probe Super Heavy (DPSH). To do the Standard Penetration Test, no correlation is required as the SPT uses the same standard energy as the DPSH- type B. The difference is that you have a 50 mm core sampling tool instead of a 20 cm² cone for the DPSH.

The Standard Penetration Test (SPT) is an in-situ dynamic penetration test designed to provide information on the geotechnical engineering properties of soil. The main purpose of the test is to provide an indication of the relative density of granular deposits, such as sands and gravels from which it is virtually impossible to obtain undisturbed samples.

To get the SPT values (no data acquisition on the GRIZZLY® for this special application), the operator just has to note the number of blows each 150 mm or 300 mm. The sample tube is driven 150 mm into the ground and then the number of blows needed for the tube to penetrate each 150 mm up to a depth of 450 mm is recorded. The sum of the number of blows required for the second and third 150mm’s of penetration is termed the “standard penetration resistance” or the “N-value”. In cases where 50 blows are insufficient to advance it through a 150 mm interval, the penetration after 50 blows is recorded. The blow count provides an indication of the density of the ground. The GRIZZLY® Standard Penetration Test (SPT) procedure meets NF P94-116 – Soil investigation and trials – Standard Penetration Test (SPT), EN ISO 22476-3:2005 Geotechnical investigation and testing – Field testing – Part 3: Standard penetration test, ASTM D1586 and Australian Standards AS 1289.6.3.1 Methods of testing soils for engineering purposes, Method 6.3.1: Soil strength and consolidation tests — Determination of the penetration resistance of a soil — Standard penetration test (SPT).

Torque Wrench

The torque wrench is used to measure the lateral friction between the material being tested and the rod stem to identify whether the torque (Nm) is within the acceptable limits including those defined by the standards NF P94-063 for control compaction.

The torque, measured before each additional 1 m rod is added, can be entered into the GRIZZLY® software and printing on the penetrograms.

Advantages

The advantages of the GRIZZLY® Dynamic Probing Super Heavy (DPSH) include:

- Faster

- Provides immediate results so that on-site decisions can be made straight away.

- Fast to setup once you have arrived on-site (10 mins) and complete a test (5-10 mins) per test typical with results viewable on site.

- Without errors

- Equipment is instrumented (data is automatically and accurately recorded)

- Results are machine produced (overcoming manual data recording, transposition or calculation errors and fictitious results)

- Improved data flow and integrity using WebSprint©

- Data export using a USB key enables further interpretation; analysis and presentation using the cloud based WebSprint©

- GPS located and time stamped – know where and when every test is done

- Visually presented results

- Graphical representation of the data (penetrogram) on the on-screen display, potting depth and cone tip resistance (qd) and your compaction control specification (reference and refusal lines)

- Improved safety

- To eliminate the need walk directly behind the GRIZZLY® in travelling mode, a remote wire controller allows the operator to be significantly distanced from the GRIZZLY® , whilst the rig is in motion.

- Versatile rubber tracked lightweight rig with a low centre of gravity, due to low height and tread width that matches the maximum width, provides the rig with great stability on difficult terrain and enables access to most site locations.

- Integrated support plate for better stability during penetration, extraction and drilling.

- Cost effective

- One person operation

- Compares favourably with Cone Penetration Test (CPT) because the GRIZZLY® can test in materials that you cannot test with a CPT (e.g. course gravels) and does not have high cost wearing parts (like CPT sensors and their calibration).

- Geotechnical drilling head option allows for 2 machines in one (drilling rig and DPSH). One can also do windowless push tube sampling and the Standard Penetration Test (SPT) with the GRIZZLY®.

- Compact highly capable DPSH rig

- Integrated powerful 11 tonnes hydraulic rod extractor

- Hydraulic vertical and lateral pole adjustment – allowing for slopes or inclinations of 25° longitudinally and 20° laterally.

- Variable Energy GRIZZLY® option increases the site characterisation range from medium to stiff materials to loose, soft soil and/or saturated sands, silts and clays.

- Good in challenging conditions, like limited physical space (e.g. buildings to be demolished), or difficult access (e.g. interior courtyards, hanging terraces, mountainous areas with no access route etc.)

- Dimensions in transport mode (L 1.86m x W 0.89m x H 1.23m)

- Weight of the GRIZZLY®(~850kg) facilitates its transport by crane, earthmoving machine or helicopter.

- GRIZZLY® can easily be loaded in a commercial vehicle for transport (no need to have a specific driver’s licence)

Applications

Applications using the GRIZZLY® Dynamic Probing Super Heavy (DPSH) constant energy heavyweight dynamic cone penetrometer method include:

- Soil investigation studies (buildings, houses, foundations and temporary works platforms, towers, platforms etc)

- Site preparation works (roads, pipes etc)

- Geotechnical diagnostics evaluations (subsidence, slope stability)

- Inaccessible sites (slopes, rough terrain etc).

Clients include those involved in pavement construction, pavement rehabilitation and investigation, material testing, site classification, soil investigation, site investigation, compaction control, geotechnical testing and geotechnical drilling. They include road authorities, councils, asset managers, mines, mobile crane operations, engineering and construction groups, subcontractors, geotechnical consultancies and research organisations.

Dynamic Probing Super Heavy (DPSH) Calibration, Service and Spare Parts

Insitutek are proud to represent Sol Solution GRIZZLY® Dynamic Probing Super Heavy (DPSH) in Australia, New Zealand and the Pacific Islands and provide a very high level of client support.

We offer a complete spectrum of services including after-sale technical support, servicing, repairs, and calibrations. Our service centre is also well stocked with spare parts and consumables.

To find out more, Contact Us.

The GRIZZLY® Dynamic Probing Super Heavy (DPSH) is a rig designed for compaction control and soil investigation to provide a measure of the in-situ strength of fine- grained and granular subgrades, base and subbase materials, and weakly cemented materials.

The GRIZZLY® Dynamic Probing Super Heavy (DPSH) is a rig designed for compaction control and soil investigation to provide a measure of the in-situ strength of fine- grained and granular subgrades, base and subbase materials, and weakly cemented materials. For dynamic probing, the depth of penetration is measured after each blow with the penetration rate expressed in mm per blow. The hammering frequency is adjustable from 20 to 30 strokes/min. The hammer is hydraulic operated allowing upwards and downwards movement and pole tilting adjustment allowing for slopes or inclinations of 25° longitudinally and 20° laterally.

For dynamic probing, the depth of penetration is measured after each blow with the penetration rate expressed in mm per blow. The hammering frequency is adjustable from 20 to 30 strokes/min. The hammer is hydraulic operated allowing upwards and downwards movement and pole tilting adjustment allowing for slopes or inclinations of 25° longitudinally and 20° laterally. tem both for depth and for the addition of rods.

tem both for depth and for the addition of rods.