Proximal Estimation of Soil Density using Sensing and Modelling

Reflecting on the better parts of 2020, Insitu Test was proud to take part in a research project as part of Smart Pavements Australia Research Collaboration (SPARC). SPARC provides an unprecedented university-led research platform for the Australian pavement industry to innovate materials, designs and adaptive technologies, facilitate skill development, and drive commercial benefits.

Led by the Department of Civil Engineering, Monash University, the research (SPARC Project IH18.06.1), focused on the proximal measurement of soil density and soil moisture, and characterisation of soil property improvement during rolling.

The research team includes:

This project involved a series of large-scale unbound pavement model soil box tests (soil box measuring 7 m long, 4 m wide and 800 mm deep) designed to undertake targeted experiments catering to several Hub projects primarily in Theme 2 – Smart sensing, construction and maintenance monitoring.

Here, SPARC Hub researchers are evaluating the performance of two types of Light Weight Deflectometers (LWDs) for assessing the compaction quality and strength of the soil during roller compaction. The two devices are ZORN ZFG 3000 and Dynatest 3032 that use different measurement techniques (accelerometer for ZORN and geophones for Dynatest) to obtain dynamic indentation depth and modulus of the soil.

Proximal Estimation of Soil Density using Sensing and Modelling (Project IH18.03.3) – Project Update

Compaction of materials (soils and unbound granular materials) in the field are carried to ensure their superior performance under repeated traffic loads. Density is an indicator of the compaction, and materials are usually compacted in the field at their Maximum Dry Density (MDD) determined at Optimum Moisture Content (OMC) using Proctor compaction in the laboratory. Achieving MDD in the field is crucial as under-compacted, over-compacted layers could cause premature failure.

The current density measurement in the field involves destructive sampling, and it does not cover the entire compacted area. The project aims to develop a novel methodology to estimate the density of soils and unbound granular materials non-destructively and in real-time during the compaction process. The methodology includes measuring the surface deformation using Light Detection and Ranging (LiDAR) systems and acceleration data from the accelerometers attached to rollers and developing a constitutive model to relate the measured parameters to the density. A theoretical cyclic model is extended and a data-driven Artificial Neural Network (ANN) model is developed. Targeted laboratory experiments are conducted to understand the material’s behaviour under given loading conditions and identify the parameters that affect the material’s deformation during compaction.

A framework that correlates the surface deformation to density has already been developed based on the laboratory experiments conducted on different materials. This framework’s suitability is currently being validated using a simulated large-scale soil box (dimensions: 7 m x 4 m x 0.8 m) experiment mimicking the field conditions. The soil box experimental plan includes testing three different materials’ compaction behaviour at three different moisture contents.

A trial test was first carried out in the first week of December 2020 to examine the sensors and systems installed on a mini roller. Fine sand was compacted in a layer of 250 mm using a 1.5-tonne mini roller instrumented with LiDAR systems, accelerometers, and a total station tracking system. The sand’s moisture content was ensured homogenous at 8% (w/w) using a concrete truck. The figure below shows sand compaction using a mini roller instrumented with LiDAR and Accelerometers.

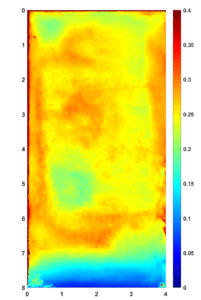

Because of the indoor setup, instead of using a GPS, the roller’s movement during compaction (including the speed and the pass count) was captured using Trimble and Sitech Universal Total Station (UTS). The surface profile of the compacted sand layer was also cross-validated using drone photogrammetry. The figure on the right side shows the soil surface profile captured using a drone system (the colour bar shows the elevation from the surface in meters).

The in situ tests for the compacted sand’s density and modulus were carried out using the sampling, Nuclear Density Gauge (NDG service was provided Geotesta), Zorn Light Weight Deflectometer (LWD), and Dynatest LWD. These measurements were validated against the LiDAR and accelerometers measurements.

The project also involves developing a new theory-based machine learning approach to fill the gap between laboratory tests and field tests. The idea of theory-based machine learning has already been successfully implemented for a 1D case.

The ZFG 3000 is an excellent tool and should be included in any professional contractors equipment list of assets. This tool should have a similar impact on the construction industry as the laser level. The ability to accurately and reliably measure this aspect of ground condition will improve the quality of the work and remove doubt as to the progress of the project.

I bought my ZFG 3000 and on the same day less than two hours later, it had paid for itself. Using this instrument, I was able to demonstrate scientifically, repeatably and independently the quality of the work that we had completed for our client. Ending the disagreement and creating an improved working relationship. Most jobs are not as confrontational as this was however, most jobs are built to a standard. The contractor can now measure as required, to know on site, at the time of testing if this standard is being achieved.

I strongly recommend the ZFG 3000 Deflectometer to any earthmoving, civil construction contractor. Good luck with your projects.

Our Plate Load equipment is getting a lot of use. We’re very happy with it. 🙂

I felt the training was very thorough. If anyone doesn’t know how to use a PANDA after that session, they shouldn’t be using one at all.

Insitutek Blogs

We find clients are often looking for ways to improve geotechnical testing outcomes and do it more efficiently at the same time. This drives their buying decision making. Australian Soil and Concrete Testing (ASCT) was a case in point when they were searching for Plate Load Test equipment for their upcoming Collector Wind Farm project. Some of the things that motivated them include: […]

We are excited to introduce the addition of a new Liquefaction Risk Estimation module in WebSprint©. Paired with our cutting-edge products, PANDA® and GRIZZLY®, this module enables you to assess the liquefaction risk of soils exposed to seismic stress. PANDA® Instrumented DCP: This cutting-edge tool provides dynamic penetrometer soundings, delivering precise data crucial for seismic risk evaluations. GRIZZLY® […]

The Australian Geomechanics Society is gearing up for a series of geotechnical events across VIC, WA, NSW, and SA-NT. We are thrilled to inform you that we will be sponsoring and attending these exciting geotechnical events, and we would love for you to join us. It’s a fantastic opportunity to catch up, explore our booth (VIC), and stay informed about […]