Top 10 trends in Site Investigation and Geotechnical Testing

We find our clients are increasingly demanding more accurate and more representative results that provide better insight on what’s going on below the surface when they are designing or constructing projects so they can make well-informed decisions in a timely manner. Having worked for nearly 15 years at the forward edge of field-testing methods that provide below the surface insight to our clients, there are some common themes we have observed. These relate to the equipment itself but also what is being measured.

- Measurement of the fundamental design parameters in the field

Clients are looking to eliminate disconnects between the design specification parameters and the as built construction assessment parameters. One of the most significant examples relates to modulus, a parameter commonly specified during the design process for flexible pavements and railway track beds. Modulus is the most accurate and independent means for judging deformation (stiffness) and, thus, a materials level of compaction. However, the current state of practice is to base the field-testing parameter selection on the result of a non-deformation parameter, such as DCP or CBR results from site investigation or density/moisture relationships in earthworks QA. This means that there is currently a disconnect between design and construction control. The Light Weight Deflectometer addresses this gap by measuring in-situ modulus directly and is locally finding support and gaining popularity.

- High levels of repeatability

There are currently used test methods like California Bearing Ratio (CBR) where 30%+ variability in results for the same material in the same condition in the same laboratory is not uncommon. This brings high levels of ambiguity to the decision-making parameters and significant additional cost as the safety factors are accordingly adjusted to cover the testing unreliability. Designers and estimators are waking up to these issues and are looking to design out such unrepeatable testing methods.

- Non destructive field testing

Methods that are less intrusive or completely non-intrusive are being favoured. It’s like comparing open-heart surgery to keyhole surgery. (overcoming damage and rectification costs and subsequent issues – think key hole surgery vs open heart surgery) Compare digging and filling in a test pit compared with a camera down-the-hole type assessment. You overcome the physical damage and rectification costs and subsequent issues.

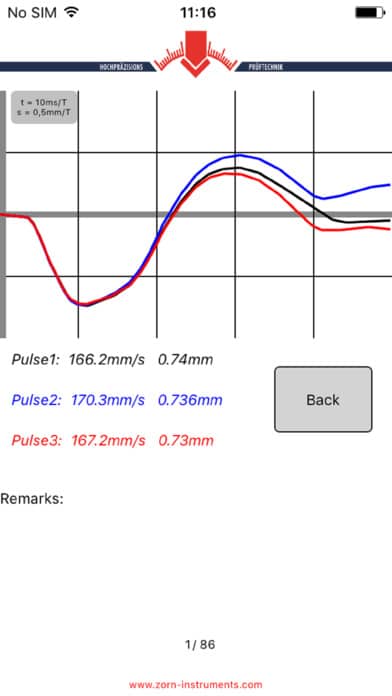

- Equipment is instrumented and results are machine produced

The electronic capture of data overcomes the issues of manual data recording and transposition errors. In Europe and increasingly in the USA for example, it is less and less common for manually recorded results to be accepted. Raw data must be captured electronically and the results output calculated using the equipment software. This eliminates calculation errors and reduces fictitious results. Lastly, clients are expecting the graphical / visual representation of the results to be immediately available at the test site to enable on-the-spot results interpretation and decision-making. Alternatively, data can be easily transferred to the decision-making engineers at another location and the outcome fed back so that appropriate action can be taken at the site.

|

|

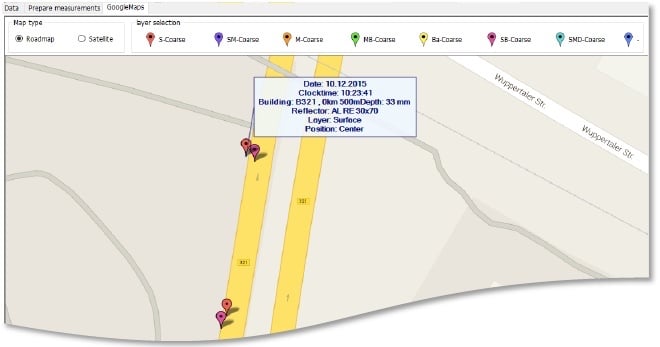

- Results are GPS located

For transparency and also for ease of test site location and data plotting, GPS is now integrated into the data collection process. There is a push now for further increasing GPS test location accuracy and integrating this with GIS (Geographic Information System) mapping.

- Improved safety

When there are test methods that significantly reduce the risk of injury (like crushing injuries with the standard DCP for example) and produce similar of better data outputs, companies can be seen to be negligent for not pursue alternative methods. We are increasing seeing government authorities and mining clients are driving these demands for safety improvements.

- Reduced time between testing and getting results

Substantially reducing the timeframe from when the test is done to when the results are produced (often real time) can create a significant advantage, compared with current methods. For example, it means continuing with earthworks, with confidence, or making real time adjustments to the placement of tie bars or thickness of asphalt / concrete layers.

- Efficient operation

Skill shortages for field technicians and geotechnical engineers and cost pressures means that more efficient testing regimes are increasingly important. Typically, we experience clients seeking one-person operation for testing procedures. Referring to the PANDA® Instrumented DCP, one of our contacts wrote: “Trialing this system in UK where the current process requires in excess of 20 personnel for window sampling. Two hours later, one window sample hole and 36 penetration profiles through ballast and formation over 1.2km distance at both rails and centre of gauge with two operatives and a lookout.”

- Greater level of coverage

Rather than measuring a small number of measuring points according to sampling plan and assuming the whole area being tested accords with the data collected, methods for a more thorough overview of the situation, supplemented by more detailed insitu testing are being favoured. Two examples come to mind:

i) Intelligent Compaction gives us an indication of how well the pavement is compacted throughout the construction site. The Light Weight Deflectometer provides calibration of Intelligent Compaction (IC) rollers output in relation to the pavement design specification (modulus value) for a specific site.

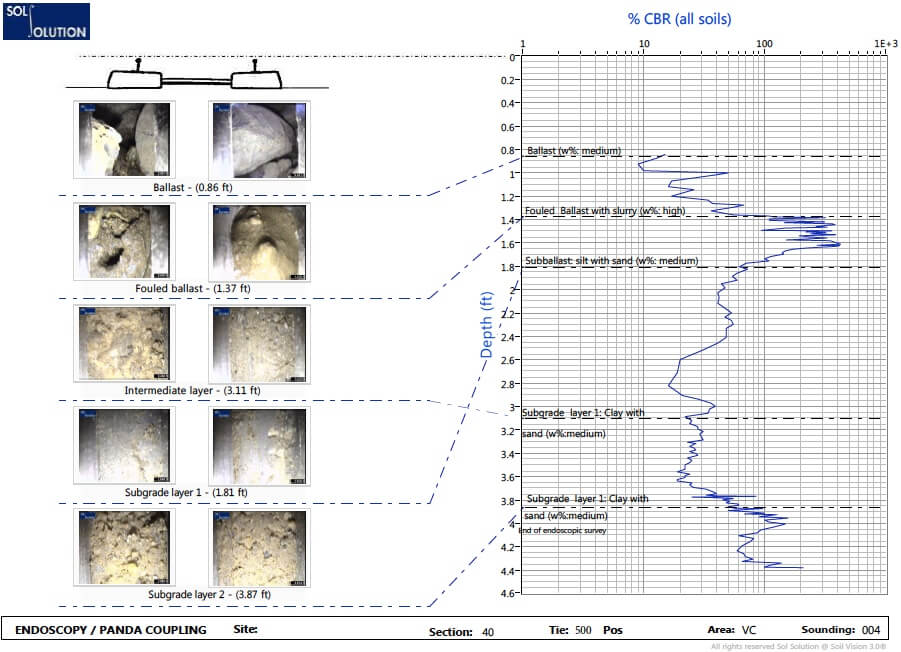

ii) A network analysis is done using Ground Penetrating Radar to gain an overall understanding of rail track ballast condition. The PANDOSCOPE® is then used to gather more information at intervals with the following outcomes:

- Layer characterisation for ballast and subgrade (identification, thickness, water content (qualitative), estimation of the soil grain size distribution and ballast condition (ballast fouling) assessment)

- Mechanical information: cone resistance (direct measurement) or CBR or other parameters with correlations.

More granularity of results

Clients are looking for a greater detail in some testing data sets. For example, testing weak materials like mine tailings with a DCP may yield no results at all, whereas with the PANDA® DCP variable energy system, less force applied to the system yields an increased number of data points and meaningful data can be collected.

Despite these technological advances, we always must remember that soils and the evaluation of their geotechnical properties is not an exact science. Through the products we supply and services we offer, Insitu Test enjoy playing our part in helping the Pacific region embrace the trends we have outlined in this article. What are your own observations regarding trends in site investigation and geotechnical testing? We’d love to hear your thoughts.

The PANDA probe is giving us and the construction team very useful insight with immediate feedback on the compaction being achieved on a major new rail construction project in QLD. We have two teams working daily using PANDA DCP’s and the Automatic Hammer on the rail formation, enabling real time decision making with confidence, based on the highly repeatable results.

FH is now routinely using the LWD with very good feedback and useful engineering data. The equipment is an easy to use Zorn LWD.

That was really useful and informative yesterday – started a lot of discussion around here.

Insitutek Blogs

We find clients are often looking for ways to improve geotechnical testing outcomes and do it more efficiently at the same time. This drives their buying decision making. Australian Soil and Concrete Testing (ASCT) was a case in point when they were searching for Plate Load Test equipment for their upcoming Collector Wind Farm project. Some of the things that motivated them include: […]

We are excited to introduce the addition of a new Liquefaction Risk Estimation module in WebSprint©. Paired with our cutting-edge products, PANDA® and GRIZZLY®, this module enables you to assess the liquefaction risk of soils exposed to seismic stress. PANDA® Instrumented DCP: This cutting-edge tool provides dynamic penetrometer soundings, delivering precise data crucial for seismic risk evaluations. GRIZZLY® […]

The Australian Geomechanics Society is gearing up for a series of geotechnical events across VIC, WA, NSW, and SA-NT. We are thrilled to inform you that we will be sponsoring and attending these exciting geotechnical events, and we would love for you to join us. It’s a fantastic opportunity to catch up, explore our booth (VIC), and stay informed about […]

More granularity of results

More granularity of results