PANDOSCOPE® for Rail Ballast & Formation Condition Assessment

- Non-destructive rail track ballast and formation condition assessment (ballast fouling)

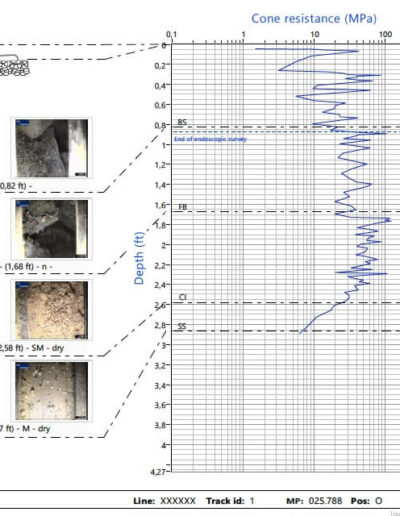

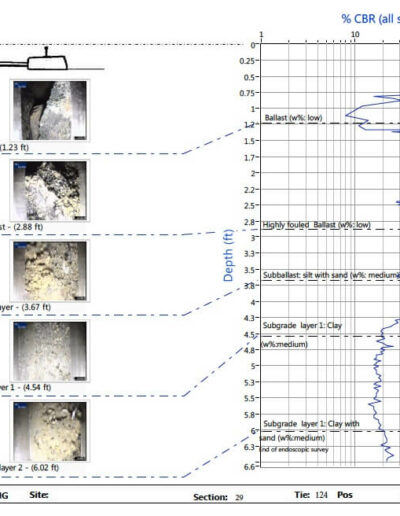

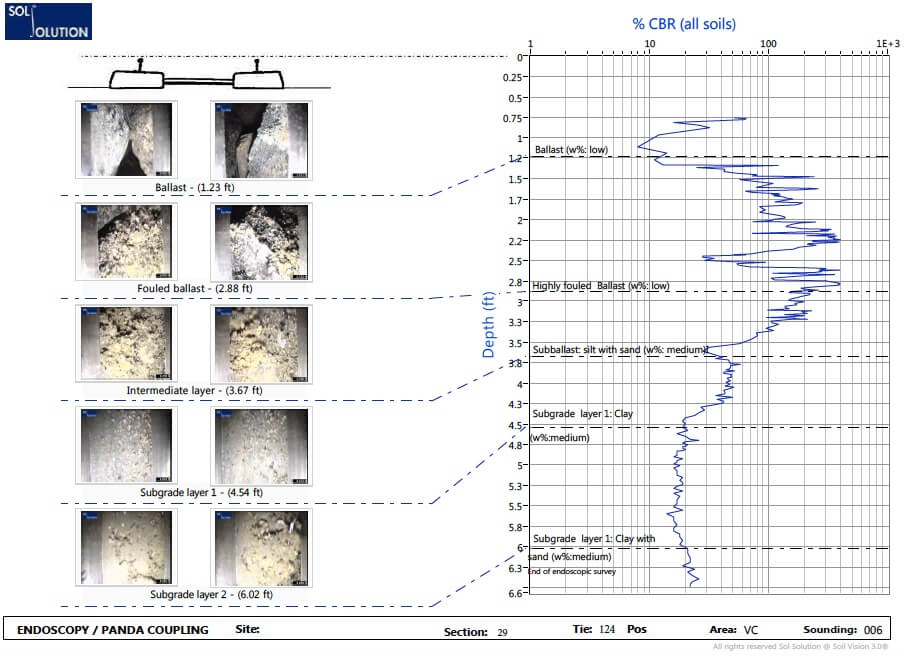

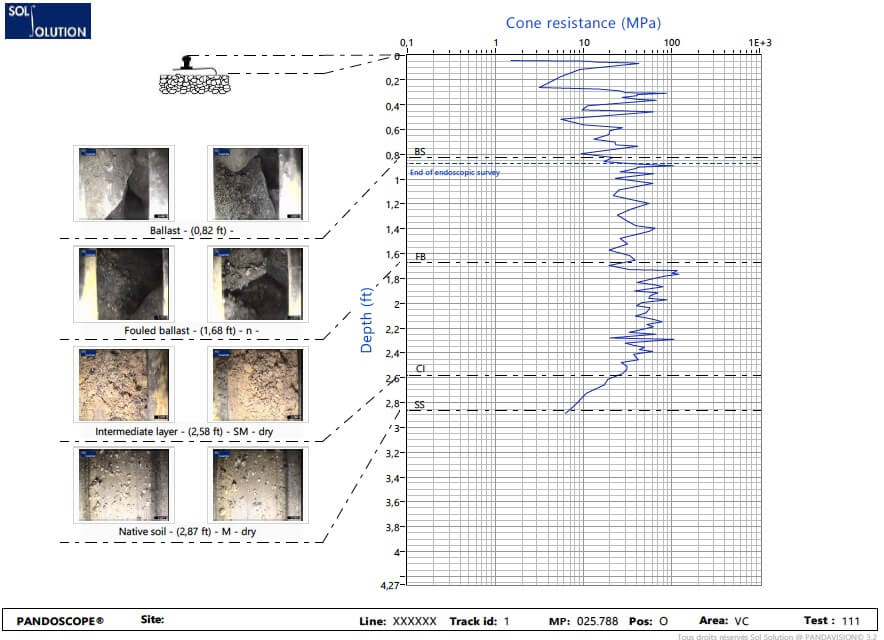

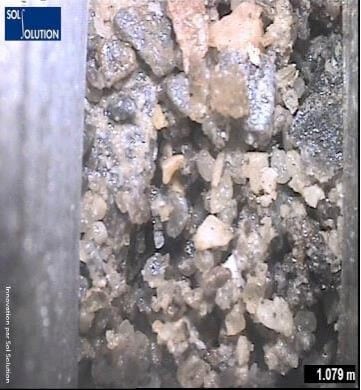

- PANDOSCOPE® Coupling of tip resistance vs depth profile with down the hole imagery

- Used for planning rail track maintenance and renewal

Applications

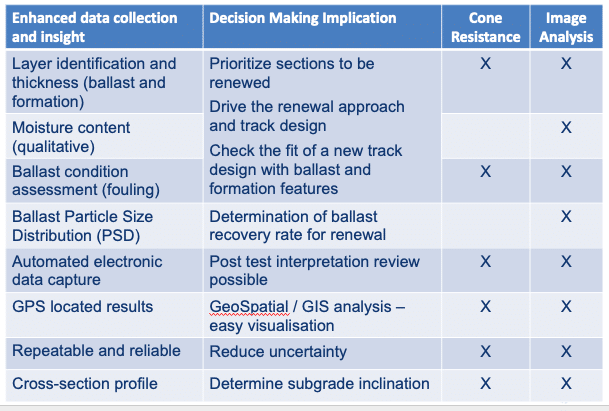

In rail applications, the PANDOSCOPE® measures geotechnical aspects of the track bed and can provide the following outcomes:

- Layer characterisation for ballast and formation (identification, thickness, water content (qualitative), estimation of the soil grain size distribution and ballast condition (ballast fouling) assessment

- Mechanical information: cone resistance (direct measurement) or CBR or other parameters with correlations

The PANDOSCOPE® data helps rail asset managers / infrastructure managers optimise the track maintenance and track renewal strategy by prioritising and allocating rehabilitation efforts and funding only to the sections that require priority attention whilst minimizing track downtime. Their objectives maybe:

- Maintain the current usage requirements

- Accommodate increases in safety, train frequency, speed and load

The PANDOSCOPE® provides engineering services with reliable geotechnical data for track design purposes. The knowledge of mechanical and physical properties of existing formation (subgrade and sub ballast layers) is very important for the future track design.

Sometimes, PANDOSCOPE® testing is combined with network Ground Penetrating Radar (GPR) data to provide more information in problem areas.

Here are some of the research papers on the PANDOSCOPE® technology rail applications.

Advantages

The PANDOSCOPE® overcomes the limitations of the majority of classical geotechnical tests (drilling rigs, pot holing). Benefits include:

- Proven approach

- Tried and tested investigation strategy for track maintenance and renewal (localised or cross network)

- Stand alone PANDOSCOPY or the coupled use of PANDOSCOPY and GPR

- Several thousand kilometres of investigations over 50,000 tests

- Passenger and heavy haul freight networks

- Several countries including France (SNCF), Belgium, USA, Canada, Singapore and Australia

- No destabilisation / disturbance of the track

- Important if renewal works are delayed or do not proceed

- Better informed decision making

- Speed and versatility

- Limited track possession time required (e.g. can test between trains working under lookout protection)

- Light weight portable equipment enables track access onto embankments and into cuttings

- Testing not limited by the height of equipment e.g. due to overhead electrification

- Cost effective methodology

- Reduced cost per hole compared to conventional approaches like potholing

- Reduced head count on site

- Less flights/accommodation required for remote site working

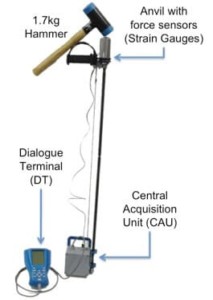

The PANDA® Instrumented Dyamic Cone Penetrometer (DCP) involves driving a variable energy cone penetration device into the rail track substructure to collect the strength (and modulus by correlation) profile with depth.

Condition monitoring of the rail track substructure layers is accomplished through insertion of a camera into the same hole, also called Geoendoscopy. The combined system is referred to as the PANDOSCOPE®. The PANDA®, PANDOSCOPE® and Geoendoscopy are all systems developed by Sol Solution.

Once the PANDOSCOPE® data has been processed, the results can be presented.

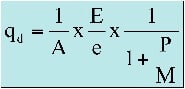

The

The  A is the cross-sectional area of the cone

A is the cross-sectional area of the cone

The Geoendoscopy test uses a tiny video camera (wired to a data logger with a soft cable) to observe the soil. The camera is introduced into the hole of a previously performed PANDA® DCP test (15 mm of diameter). The collection of imagery from down the hole allows a qualitative characterisation of soil.

The Geoendoscopy test uses a tiny video camera (wired to a data logger with a soft cable) to observe the soil. The camera is introduced into the hole of a previously performed PANDA® DCP test (15 mm of diameter). The collection of imagery from down the hole allows a qualitative characterisation of soil.